Adjusting Inventory: Identify & Prevent

Built For

Adjusting Inventory: Identify & Prevent explores causes of inventory adjustments and offers solutions on how multi-channel retailers can reduce their frequency.

Adjusting Inventory

The profitability of product-selling businesses relies heavily on accurate inventory tracking and real-time operational visibility. When the need for adjusting inventory becomes a frequent occurrence, warehouses and inventory are not being managed properly. Businesses relying on manual or disjointed systems to manage inventory are often plagued with inaccuracies and errors, causing an abundance of financial discrepancies. Inventory adjustments can be costly for a business, obscuring true costs of goods, profit margins, and bottom lines. While not all inventory adjustments can be prevented, the frequency can be curbed with the right tools.

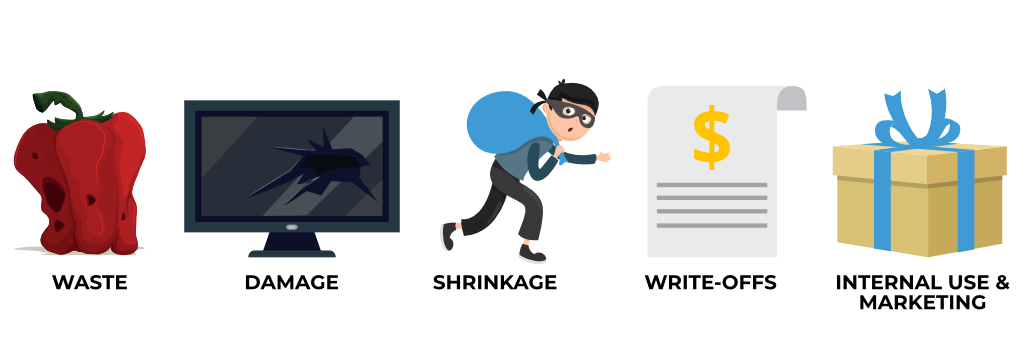

Adjusting Inventory: 5 Common Reasons

- Waste: Inventory waste happens for a variety of reasons like over-production, expired or obsolete inventory, bottlenecks, and overprocessing.

- Breakage: Inventory breakage is a result of goods that have been damaged in some way and are no longer available for legal sale.

- Shrinkage: Inventory shrinkage refers to theft from the warehouse by an employee.

- Write-offs: Inventory write-offs remove the value of a portion of inventory from accounting records when value is lost for a variety of reasons.

- Internal: Internal reasons for inventory adjustments come from either being consumed by the company or used for marketing materials, such as providing free samples.

Regardless of the reason, transactions adjusting inventory should be few and far between, not a daily problem. If it is a common problem, the manual processes and disjointed systems mentioned above could certainly be to blame. Increasing visibility into inventory and improving warehouse efficiency leads to more accurate inventory management and less inventory adjustments.

Acctivate offers solutions to prevent inventory adjustments and keep books accurate.

Adjusting Inventory: More Control for Warehouse Staff

When only one or two people in an organization are responsible for posting receipts, the higher the likelihood for error – especially if those responsible are far removed from the daily goings on in the warehouse. Providing warehouse teams with the ability to post transactions based on inventory movements within the warehouse ensures accuracy of the transactions which in turn reduces the need to create and post inventory adjustments. Acctivate provides users from across an organization the control and access they need to monitor, control, and track inventory and warehouse operations in real-time, while also providing user permission settings where they are required. With Acctivate, inventory movement, adjustments, and status changes are captured and managed through the use of transactions, easily managed on one screen.

Adjusting Inventory: Performing Regular Cycle Counts

Performing regular cycle counts is key to ensuring inventory is accurate. Cycle counts quickly identify inventory discrepancies caused by damaged, misplaced, miscounted, or stolen stock, and help ensure inventory listed as available is truly available. In Acctivate, inventory is counted in an incremental method with all inventory being recorded in sections over time versus all at once. A business can choose when to perform the counts, what SKUs to be counted, and how often the process is completed. With the addition of barcode software, the process of cycle counts is streamlined and highly accurate, as opposed to traditional counting and tracking methods where human errors are likely to occur – and with errors comes the need for adjusting inventory.

Adjusting Inventory: Ensuring an Accurate Receiving Process

The receiving process is highly susceptible to inventory inaccuracy with items received miscounted, correct number of goods assumed, and damaged or spoiled inventory overlooked until it’s been placed on the shelves. Again, with the addition of barcoding software and Acctivate, inventory receiving can become much smoother, more efficient, and a highly more accurate process, which leads to fewer adjustments down the line. Through warehouse optimization and organization, such as bin locations and barcodes, and tools to handle variances easily on the spot – the need for adjusting inventory based on inaccurate numbers or the reception of damaged goods is mitigated sooner.

Adjusting Inventory with Acctivate

Acctivate Inventory Software provides an arsenal of features and tools designed to improve inventory management and warehouse operations for small and mid-sized multi-channel retailers using QuickBooks. Removing manual processes or eliminating disjointed outdated software solutions is the first step to transforming a business into a well-oiled, accurate, high-performing machine.

Call us at 817-870-1311