Barcode Basics

Built For

Barcode basics: Standards

Today, we are going to cover the barcode basics regarding barcodes and product codes. We’ll begin with an example of produce.

Product information for produce is regulated by the International Federation for Produce Standards. Most other food items and consumer goods that you can find around the house or workplace use product code standards created by the GS1 organization.

“The GS1 System provides for the use of unambiguous numbers to identify goods, services, assets, and locations worldwide. These numbers can be represented in barcodes to enable their electronic reading wherever required in business processes. The system is designed to overcome the limitations of using company, organisation, or sector specific coding systems, and to make trading much more efficient and responsive to customers.”[1]

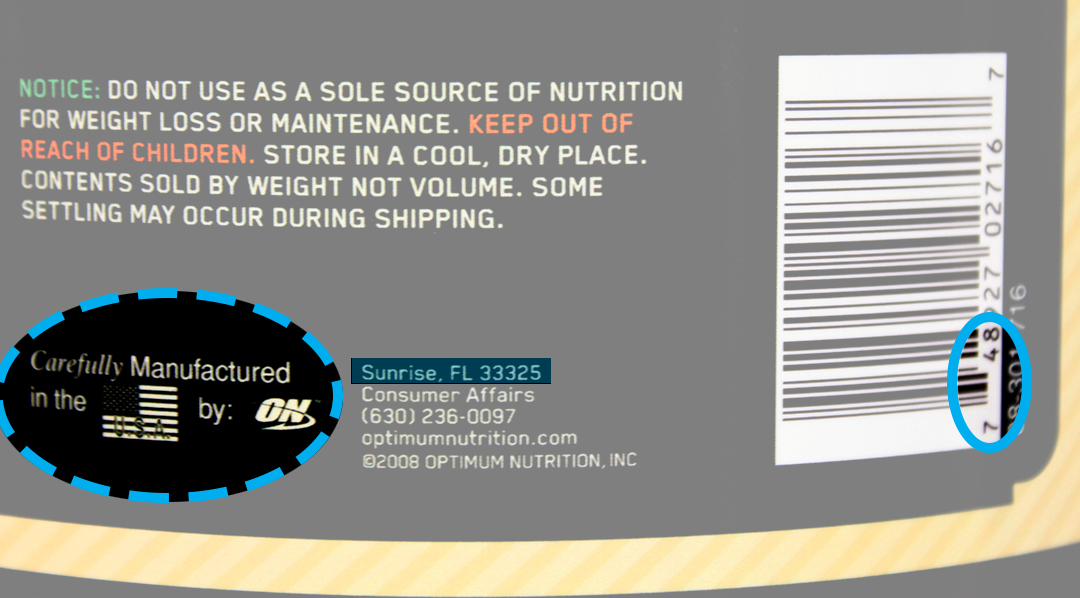

Here is a side-by-side comparison of the barcode labels usually found on produce (left) and packaged goods (right):

As you can see, the produce sticker contains an image of its origin (the yellow semicircular image), barcode (the thin and thick black lines), and a product code (4046).

In contrast, the packaged item’s product identifier is a U.P.C. barcode: barcode lines (the thin and thick black lines) with a product code (the series of numbers under the barcode)[2]. The string of numbers underneath the barcode lines make up the item’s Global Trade Item Number®, or GTIN®[1]. Packages and shipments, as well as warehouse containers and units, utilize a separate system for standardized identifying numbers created by the GS1.[3]

The GTIN is a standardized method of assigning a universally recognizable product code to an item, which is helpful for consumers, distributors, manufacturers, and anyone involved in the supply chain. Per the GS1, the GTIN:

“…uniquely identifies trade items at all item and package levels, thus ensuring that they are always identified correctly anywhere in the world. Each trade item that is different from another is allocated a separate, unique GTIN.”[1]

Here is an example of a GTIN from GS1’s website[4]:

Most items that can be bought by consumers include a GTIN-12 or a GTIN-13 to accompany the barcode; the numbers following simply refer to the number of digits in the GTIN[5]. These are the items you would most likely buy from a grocery store or retail store.

A GTIN is comprised of three elements[6]:

- A U.P.C. company prefix

- Item reference number

- Check digit

In order to receive a U.P.C. company prefix, a company must apply to GS1 and have one assigned to them.[5] From there, the company will assign GTINs to all items they manufacture using their designated U.P.C. company prefix. The company prefix is unique to each company and is a way to identify the company that claims ownership of a product[7].

However, the GS1 states…

“Note that since GS1 member companies can manufacture products anywhere in the world, GS1 prefixes do not identify the country of origin for a given product.”[8]

So purely going off of the first digits you see on a product label to determine where it was manufactured can be misleading for many reasons, including:

– U.S. companies are assigned a company prefix starting with the number ‘0’[7]. However, those companies may not include the ‘0’ in the beginning of their product label GTIN numbers.

– As noted by the GS1, a U.S. GS1 registered company may manufacture their products in another country or other countries.

So as a consumer, the best way to know where a product was manufactured is to look for a “Made In…” label. Additionally, you can find out what company the product is registered under using GS1’s handy GTIN search tool.

Barcode basics: How a barcode inventory management system is used in business

So we learned about barcodes and GTINs from a consumer standpoint, but how are they actually utilized by businesses?

As far as the U.P.C. barcode lines, the barcodes can be scanned to maximize productivity and accuracy in the warehouse or store.

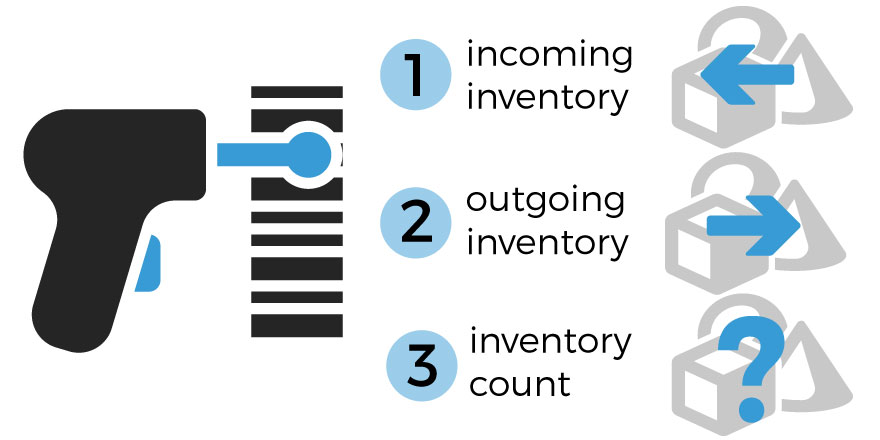

For instance, barcodes can be scanned to:

- receive inventory in the warehouse or store

- pick items and fulfill orders

- conduct inventory counts and verify inventory

GTINs provide a way for businesses to identify a product. This is in conjunction to other identifiers such as:

- SKUs

- serial and lot numbers

- internal product ID

- product description

These identifiers can be associated with the related product in an inventory management system. Having multiple product IDs and descriptions are helpful when looking up an item in a database.

Barcode inventory management can be a useful tool, especially for those businesses that handle many products, have a warehouse or warehouses, or simply want to reduce the amount of time spent on inventory management while increasing accuracy. To learn more about barcodes and barcoding, check out our barcoding and mobile page for how you can utilize barcodes in your business or warehouse.

References

1. GS1’s ‘An Introduction to the Global Trade Item Number (GTIN)’, 2. GS1’s ‘About the GS1 Company Prefix’, 3. GS1’s ‘GS1 Standards’, 4. GS1’s ‘Search by GTIN’ tool, 5. GS1’s ‘GS1 General Specifications’, 6. GS1’s ‘Create Your Product or Location Identification’, 7. GS1’s ‘Get a Licensed GS1 Company Prefix’, 8. GS1’s ‘GS1 Company Prefix’ listings

Call us at 817-870-1311