How do you forecast inventory?

Built For

Brian Sweat, VP & GM of Acctivate inventory software, discusses what it takes to ensure you have the right amount of stock on hand.

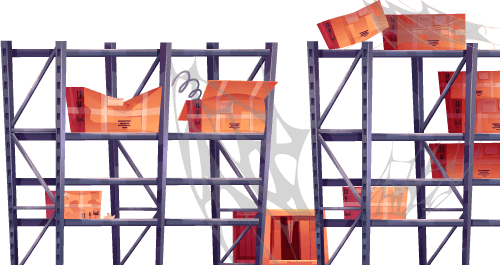

Have you ever found yourself in the warehouse, surrounded by piles of products that don’t seem to budge? Or worse, faced the dreaded shelf ghost-town where that hot-ticket item should be sitting? It’s the classic tale of inventory woes – too much of one thing, not enough of the other. It’s like Goldilocks in the business world, but the porridge is either frozen solid or boiling over.

Which brings us to today’s topic: How do you forecast inventory? This isn’t about gazing into crystal balls or reading tea leaves. No, it’s about using a mix of intelligent data, a bit of business savvy, some good ol’ common sense, and, preferably, some inventory management software to make sure you’ve got just the right amount of stock on hand – not too hot, not too cold, but just right.

Why should you care? Well, nailing your inventory forecast is like finding that sweet spot on your favorite couch – it’s comfortable, makes you happy, and feels right. It means you’re not throwing cash into the abyss of storage costs and not sending customers away with empty hands and frowns. Instead, you’re running a tight ship where products easily flow in and out of the warehouse.

Understanding Inventory Forecasting: The What, Why, and The Oh-So-Glorious How

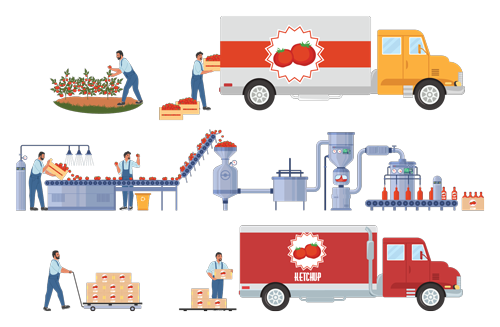

Inventory forecasting is like your business’ personal weather report, but instead of predicting rain or shine, it’s all about predicting the ebb and flow of your products. Inventory forecasting is the process of estimating the amount of product your company will sell and determining what you need to keep in stock to meet customer demand without overdoing it.

Why it’s a big deal:

- Say goodbye to cash traps: Overstocking is like a money-eating monster in disguise. It ties up your hard-earned cash in products that just sit there, collecting dust.

- No more customer sad faces: Understocking is the fast track to customer frowns, which is bad for business and even worse for your rep.

- Hello, sweet efficiency: When you forecast right, you can plan better, reduce waste, and keep everything running smoothly.

The nitty-gritty of the how:

- Past sales data is your BFF: Look back to leap forward. Analyze those numbers to spot trends, patterns, and rhythms of sales.

- Know thy market: Stay hip to market trends, seasonality, and those pesky economic factors that can turn your sales graph into a roller coaster.

- Tech to the rescue: Leverage software tools that crunch the numbers, analyze data, and serve forecasts on a silver platter.

The Basics of Inventory Forecasting: Your Starter Kit

So, you’re ready to jump into inventory forecasting, but where do you start? Think of this as your inventory forecasting starter kit – add data, stir in some analysis, and voilà!

Know your ABCs (Always Be Counting)

- Inventory count: You can’t manage what you don’t measure. Keep a regular tally of what’s in stock. Handling it manually is about as fun as watching paint dry, but it’s the cornerstone of forecasting.

- Stock Keeping Units (SKUs): These little codes are like DNA for your products – unique identifiers that track each item. Keep them organized, and you’ll avoid a world of confusion.

Historical sales data – Your crystal ball

- Sales trends: These are the patterns in your past sales that are as telling as a fortune teller with a crystal ball. Was there a spike in umbrella sales every time it rained cats and dogs? That’s a trend worth noting.

- Seasonality: Santa hats in December, sunscreen in July. Some items are as predictable as tax season, and you’ll want to stock up accordingly.

Demand planning – Anticipate and act

- Customer demand: Keeping a pulse on what your customers are clamoring for means staying one step ahead of the game.

- Product lifecycles: Products are like reality TV stars; they have a rise, peak, and fall. Know where each product is in its lifecycle to forecast better.

The forecasting formula – Not just a numbers game

- Quantitative data: This is where you get down with numbers – using mathematical models to predict future sales based on historical data.

- Qualitative insights: Sometimes, you need that human touch – using your industry knowledge, market trends, and maybe a little gut instinct to adjust the numbers.

Embrace technology – Your digital sidekick

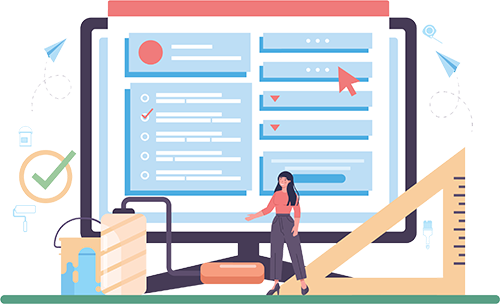

If you started to squirm when you hit “mathematical models” in that last paragraph and are having flashbacks to college statistics class, hold on. There is an easier and better way. Inventory management software with forecasting capabilities is your versatile and powerful ally in the quest to hit that inventory sweet spot. With a few clicks, inventory software can analyze heaps of data, spot hidden trends, and spit out predictions faster than you can say “stock optimization.”

The benefits? Oh, they’re sweet. Imagine slashing the time you spend on spreadsheets, waving goodbye to gut-feel guesses, and meeting customer demand with the precision of a finely tuned orchestra. It’s about getting a handle on the complexities of your inventory without breaking a sweat. Integration with your existing systems means this software doesn’t just work for you; it works with you, creating a seamless flow of information that keeps your business humming along efficiently. So, by embracing these tech tools, you’re not just simplifying the forecasting process; you’re turbocharging it.

Leveraging Inventory Software for Precise Sales and Demand Forecasting

Imagine a world where you can anticipate your customer’s needs even before they do. That’s the power of modern inventory software – it’s not just a tool; it allows you to quickly pivot in response to customer whims, shifting market trends, or unexpected events and can significantly boost your profitability.

The insightful edge

Intelligent decisions in business are rooted in insights, not hunches. With the right inventory software, you have a fountain of wisdom at your fingertips. These tools don’t just drown you in data; they serve up actionable insights on a silver platter, suggesting the moves you can make to stay ahead of the game. It’s about speed, ease, and precision wrapped up in one slick package.

Forecasting tools – Your inventory oracle

These technological marvels are your ally in understanding and optimizing your inventory levels. They’re not just about keeping stock but about keeping the right stock. By improving your purchase management through guidelines and analytics, you simultaneously elevate customer satisfaction and your bottom line.

Tackling understocking with demand planning

You’ve heard it before – you can’t sell what you don’t have. But the sting of a lost sale goes deeper than just the missed profit. Think of the marketing dollars spent to draw in that customer, the tarnished business image, and the possibility that the customer might not give you a second chance. Inventory forecasting software is your sentinel against such scenarios, helping you prevent lost sales and the ripple effect they cause.

Trend analysis – The intelligent approach

Rather than chasing the tail of every lost sale, use your inventory software to analyze buying trends for a more precise prediction of future needs. It’s about being proactive, not reactive. And beware the ghost of phantom inventory – products that the system says you have, but in reality, have vanished (that’s scary). Your software is the ghostbuster here, ensuring that phantom inventory doesn’t lead to real-world out-of-stocks.

The bigger picture with sales analysis

In a competitive marketplace, customer satisfaction is the currency of success. By looking at your business from a bird’ s-eye view—sales, purchasing, operations, and warehouse—you gain the power to implement improvements that resonate across the board. Sales analysis isn’t just about counting numbers; it’s about shaping your entire supply chain, from marketing strategies to warehouse management, ensuring that your most profitable customers always receive VIP treatment.

Reorder analysis – The trifecta of inventory questions

Finally, the big questions – what, how much, and when to reorder – are answered not by guesswork but by your software’s reorder analysis capabilities. Inventory software helps establish precise reorder points, alerts you when stocks are low, and can send purchase orders with a click. This level of control means you’re not just responding to your business needs; you’re anticipating them.

How do you forecast inventory? FAQs

How do you forecast inventory?

Inventory forecasting is estimating future product sales and purchasing the correct amount of stock to meet customer demand without buying too much inventory.

How can inventory software improve my sales forecasting?

Inventory software can analyze past sales data, identify trends and patterns, and use this information to predict future sales more accurately, helping you anticipate customer demand, make informed decisions about stock levels, and ensure you’re prepared for what’s coming.

How can inventory forecasting tools help my business?

The benefits include improved efficiency by automating data analysis, better customer satisfaction through avoiding stockouts, reduced costs by minimizing excess inventory, and the ability to make faster, better-informed decisions based on actionable insights provided by the software.

Can inventory software help me better understand customer demand?

Absolutely! By analyzing sales trends and buying behavior, inventory software provides a clearer picture of what your customers want, when they want it, and in what quantities, enabling you to adapt your inventory levels accordingly.

How does inventory software deal with the issue of phantom inventory?

Inventory software tracks actual sales and stock levels in real time, reducing the likelihood of phantom inventory – items that appear in stock in the system but aren’t physically available, helping ensure that purchase orders are accurate and preventing out-of-stock situations.

Will implementing inventory forecasting software affect other areas of my business?

Yes, in a positive way. Sales analysis provided by the software can lead to better purchasing and production planning, improved ROI on marketing plans, more efficient supply chain management, and enhanced overall service for your most profitable customers, benefiting the entire business operation.

Call us at 817-870-1311