Improve Your Business with Operational Analysis

Built For

Improve Your Business with Operational Analysis

One of the most effective ways to ensure your business runs smoothly is through operational analysis. By understanding how each part of your operation works and how they interconnect, you can make informed decisions that drive improvement and growth.

Operational analysis might sound a bit intimidating, but it doesn’t have to be. With the right tools, such as inventory and order management software, you can easily gather, analyze, and act on valuable data. The software not only streamlines your operations but also provides real-time insights needed for making intelligent business decisions.

In this article, we’ll explore how leveraging inventory and order management software can enhance your operational analysis, significantly improving efficiency, productivity, and profitability. Let’s dive in and discover how you can elevate your business with the power of operational analysis.

Understanding Operational Analysis

Operational analysis is all about examining your business processes to understand how well they are functioning and where there is room for improvement. It involves looking at various aspects of your operations and analyzing data to identify trends, inefficiencies, and opportunities for enhancement.

Operational Analysis Definition and Key Components

Operational analysis is the process of reviewing and assessing the performance of your business operations. The goal is to understand how your operations are performing and find ways to improve efficiency, reduce costs, and boost overall productivity. Critical components of operational analysis include:

- Data Collection is the process of gathering accurate and relevant data from various parts of your business.

- Data Analysis uses tools and techniques to analyze this data and extract meaningful insights.

- Performance Metrics Identify and track key performance indicators (KPIs) that measure the success of your operations.

- Continuous Improvement involves implementing changes based on your analysis to enhance performance and regularly reviewing the impact of these changes.

Common Operational Analysis Methods and Tools

Several methods and tools can help you conduct operational analysis effectively:

- Flowcharts and Process Maps provide a visual representation of your processes that help identify bottlenecks and areas for improvement.

- Benchmarking compares your business performance against industry standards or competitors to identify best practices and performance gaps.

- SWOT Analysis is evaluating your business’s strengths, weaknesses, opportunities, and threats to clearly understand where you stand and where you can improve.

- Inventory and Order Management Software provides real-time data and analytics capabilities, making tracking performance, identifying issues, and making data-driven decisions easier.

By understanding the basics of operational analysis and utilizing the proper methods and tools, you can gain valuable insights into your business operations that drive continuous improvement.

Benefits of Using Inventory and Order Tracking Software for Operational Analysis

Inventory and order management software is a crucial tool that simplifies and assists with analyzing business operations.

Accurate Data Collection and Reporting

One of the most significant challenges in operational analysis is collecting accurate and up-to-date data. Inventory and order management software automates data collection, reducing the risk of human error. Inventory and order management software provides comprehensive reports that give you a clear view of your inventory levels, order statuses, and overall operational performance.

Real-Time Insights into Business Operations

You can access real-time data and insights with inventory and order management software. This means you can monitor your operations as they happen, allowing you to quickly identify and address any issues. Real-time insights help you stay on top of your business, ensuring you can make timely and informed decisions.

Enhanced Decision-Making Capabilities

Having accurate and real-time data at your fingertips enhances your decision-making capabilities. You can analyze trends, forecast demand, and make strategic decisions that drive efficiency and profitability. Inventory and order management software equips you with the necessary information to make smarter, data-driven decisions.

Improved Efficiency and Productivity

Inventory and order management software significantly improves operational efficiency by streamlining and automating routine tasks. The software can handle tasks like order processing, inventory tracking, and reporting, freeing your team to focus on more strategic activities. The result is a more productive and efficient operation.

Enhanced Customer Satisfaction

With the help of inventory and order management software, operational analysis leads to improved order fulfillment rates and faster delivery times. This directly impacts customer satisfaction, as your customers receive their orders accurately and on time. Happy customers are likely to purchase with you again, boosting your sales and reputation.

Key Features of Inventory and Order Management Software for Operational Analysis

Inventory and order management software has features that enhance your operational analysis capabilities. Here are some of the key features that make this software indispensable for any business looking to optimize its operations:

Customizable Dashboards for Monitoring Key Performance Indicators (KPIs)

One of the standout features of inventory and order management software is the customizable dashboards. These dashboards allow you to monitor KPIs critical to your business’s success, tracking metrics such as inventory turnover rates, order fulfillment times, and sales trends in real time. Customizable dashboards ensure a precise, at-a-glance view of business performance, enabling data-driven decisions.

Advanced Reporting and Analytics Tools

The advanced reporting and analytics tools inventory and order management software provides are essential for deep operational analysis, allowing you to generate detailed reports on your operations, from inventory levels to sales performance. The reports can be used to pinpoint inefficiencies, identify trends, and uncover opportunities for improvement.

Integration with Other Business Systems

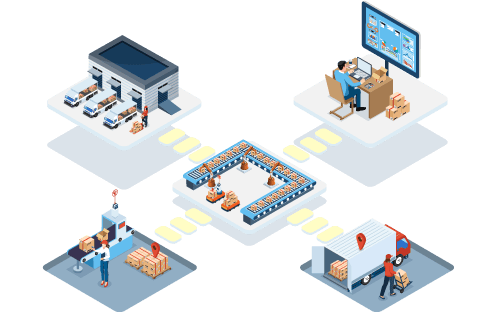

Another key feature of inventory and order management software is seamless integration with other business systems, such as QuickBooks and eCommerce platforms, ensuring data flows smoothly between your different systems, providing a comprehensive view of your business operations. By centralizing data from various sources, you can perform more accurate and holistic operational analysis.

Alerts and Notifications

Inventory and order management software includes alerts to inform you about critical events. Alerts for low stock levels, overdue shipments, and other important milestones can be established. These notifications help you stay proactive, allowing you to address issues prior to escalation, ensuring smooth operations.

By leveraging these key features, inventory and order management software empowers you to conduct thorough operational analysis, improving efficiency, productivity, and overall business performance.

Improving Inventory Management through Operational Analysis

Real-time inventory tracking is a crucial feature that helps you maintain optimal stock levels and reduce the risk of stockouts or overstock situations. The software continuously monitors your inventory, updating stock levels, locations, and movements, and enabling you to make informed decisions about reordering, stocking, and allocation, ensuring your inventory is always in sync with demand.

Monitoring Inventory Levels and Turnover Rates

By closely monitoring how quickly your inventory is moving, you can make informed decisions about reordering and stocking. High turnover rates indicate strong product demand, while low turnover rates might suggest overstocking or slow-moving items. Analyzing this data helps you adjust your inventory strategies to match demand, reducing the risk of excess stock or stockouts.

Identifying Slow-Moving and Obsolete Stock

Operational analysis can help you identify a slow-moving, obsolete stock that ties up valuable resources and space. Inventory management software allows you to generate reports highlighting items with low sales velocity. By identifying these products, you can take action to clear out slow-moving stock, such as offering discounts or bundling them with more popular items. This frees up space for more in-demand products and improves your cash flow.

Optimizing Stock Levels to Meet Demand

Using operational analysis, you can optimize your stock levels to ensure you have the right inventory to meet customer demand. Inventory management software provides insights into sales trends, seasonal variations, and customer buying patterns. By analyzing this data, you can forecast future demand more accurately and adjust your inventory levels accordingly. This helps you maintain a balanced inventory, avoiding overstocking and stockouts and ensuring you can promptly fulfill customer orders.

Enhancing Supplier Management

Operational analysis also plays a vital role in supplier management. Inventory management software tracks supplier performance, including lead times, order accuracy, and delivery reliability. By analyzing this data, you can identify the most reliable suppliers, negotiate better terms, or find alternatives for underperforming ones. Improved supplier management leads to more consistent inventory levels and fewer disruptions in your supply chain.

Reducing Holding Costs and Increasing Efficiency

Effective inventory management through operational analysis helps reduce holding costs associated with storing excess inventory. Maintaining optimal stock levels and minimizing slow-moving or obsolete items can lower warehousing expenses and improve your overall efficiency. Inventory management software provides the tools to streamline inventory processes, from receiving and storage to picking and shipping, critical factors in achieving faster and more accurate operations.

Enhancing Order Management with Operational Analysis

Efficient order management and fulfillment capabilities are at the heart of inventory and order management software. The software automates order processing, from receiving orders to picking, packing, and shipping. This automation reduces manual errors, speeds up the fulfillment process, and improves accuracy. By optimizing order management, you can ensure customers receive their orders promptly, enhancing customer satisfaction and loyalty.

Tracking Order Fulfillment Rates and Times

Operational analysis allows you to track order fulfillment rates and times accurately. Order management software provides detailed reports on how long it takes to process, pick, pack, and ship orders. Analyzing this data lets you identify bottlenecks and inefficiencies in your order fulfillment process. Understanding these metrics helps you streamline operations, reduce fulfillment times, and improve customer satisfaction.

Analyzing Order Patterns and Trends

Order management software allows you to analyze order patterns and trends over time. This analysis helps you understand your customers’ buying behaviors, peak ordering times, and seasonal demand variations. With this information, you can adjust your inventory levels, staffing, and order processing procedures to better align with demand, ensuring you are always prepared to meet customer needs.

Improving Customer Satisfaction Through Timely Deliveries

Timely delivery is crucial for customer satisfaction. Operational analysis helps you ensure that orders are processed and delivered on time. By monitoring key performance indicators such as fulfillment speed, order accuracy, and delivery times, you can make necessary adjustments to your processes ensuring customers receive their orders correctly and promptly, leading to higher satisfaction and increased customer loyalty.

Reducing Order Processing Errors

Order management software helps reduce processing errors by automating many tasks to fulfill orders. Operational analysis allows you to identify familiar sources of errors, such as incorrect data entry or picking mistakes. By addressing these issues, order accuracy can be improved, reducing returns and exchanges, and enhancing overall efficiency.

Enhancing Communication and Collaboration

Effective order management requires seamless communication and collaboration among departments, such as sales, warehouse, and customer service. Order management software facilitates better communication by providing a centralized platform where all relevant information is accessible. Operational analysis helps you understand how different teams interact and identify areas where communication can be improved. Enhanced collaboration leads to faster problem resolution and more efficient order processing.

Leveraging Automation for Efficiency

Automation is a powerful tool for enhancing order management. Order management software automates repetitive tasks such as order entry, invoicing, and shipment tracking. Operational analysis helps you identify which tasks can be automated for maximum efficiency, allowing your team to focus on more strategic activities and speeding up the order fulfillment process.

Call us at 817-870-1311