Improving Picking Efficiency with Inventory Software

Built For

Improving Picking Efficiency with Inventory Software

Efficiency is vital in warehouse management. One of the most critical aspects of this efficiency is the picking process. Picking, the act of collecting items from inventory to fulfill orders, can make or break your operation. Imagine the chaos of misplaced items, incorrect orders, or a slow picking process – not only does it frustrate your team, but it also impacts your customers’ satisfaction.

Fortunately, technology offers a solution. Inventory software transforms how warehouses operate, particularly in how they handle picking tasks. With the right software, you can streamline your picking process, reduce errors, and boost productivity. In this article, we’ll explore how inventory software can significantly improve picking efficiency, ensuring your warehouse runs smoothly and your customers remain happy.

Understanding Picking Efficiency

Picking efficiency is all about how effectively and accurately items are collected from inventory to fulfill orders. It’s a crucial part of the order fulfillment process that directly impacts your warehouse’s productivity and customer satisfaction. But what exactly does picking efficiency entail, and how can you measure it?

Picking Efficiency Definition

Picking efficiency refers to the accuracy and speed with which warehouse staff can locate and retrieve items for shipment. Efficient picking means orders are fulfilled quickly and correctly, minimizing delays and errors that could lead to customer dissatisfaction.

Key Metrics to Measure Picking Efficiency

To understand and improve your picking efficiency, it’s essential to track specific metrics:

- Order Accuracy measures the percentage of orders picked without errors. High order accuracy means customers receive the correct items in the right quantities.

- Pick Rate is the number of items picked per hour or shift. A higher pick rate indicates a more efficient picking process.

- Cycle Time is the total time it takes from receiving an order to preparing it for shipment. Shorter cycle times are a sign of efficient operations.

- Travel Time is the amount of time pickers spend moving around the warehouse. Reducing travel time can significantly boost picking efficiency.

- Labor Utilization is how effectively your workforce is used in the picking process. Optimizing labor utilization means maximizing productivity while minimizing wasted effort.

Focusing on these metrics can help you gain a clearer picture of your current picking efficiency and identify areas for improvement. Inventory software can provide the tools to enhance these metrics, leading to a more streamlined and effective picking process.

Challenges in Traditional Picking Processes

Traditional picking processes, often reliant on manual methods, come with many challenges that can hinder efficiency and accuracy. Understanding challenges is the first step toward overcoming them with modern solutions like inventory software.

Common Issues Faced in Manual Picking

- Human Error: Manual picking is prone to mistakes such as selecting the wrong item or incorrect quantities. These errors can lead to order inaccuracies and dissatisfied customers.

- Time-Consuming: Without optimized paths or systematic approaches, pickers can spend significant time locating items. This results in slower order fulfillment and longer cycle times.

- High Labor Costs: Inefficiencies in the picking process often require more labor to meet demand, leading to higher operational costs. Over-reliance on manual labor also means more room for variability in performance.

- Difficulty in Managing Inventory: Manual processes make keeping accurate, real-time inventory records challenging. This can lead to stock discrepancies, overstocking, or stockouts, further complicating the picking process.

- Lack of Real-Time Visibility: Traditional methods do not provide real-time updates on inventory status, making tracking the exact location and availability of items difficult. This can cause delays and miscommunication.

Impact of Inefficiencies on Overall Warehouse Performance

- Delayed Order Fulfillment: Inefficiencies in picking slow down the entire order fulfillment process, leading to delayed shipments and unhappy customers.

- Increased Operational Costs: The need for more labor and time to correct mistakes or manage manual processes increases operational expenses, impacting the bottom line.

- Lower Employee Morale: Repeated mistakes, inefficient workflows, and constant pressure to meet demand can lead to frustration and lower morale among warehouse staff.

- Customer Dissatisfaction: Errors and delays in order fulfillment directly affect customer satisfaction, leading to potential loss of business and a damaged reputation.

These challenges highlight the limitations of traditional picking processes and underscore the need for more advanced solutions. Inventory software addresses these issues, streamlines operations, and improves picking efficiency.

How Inventory Software Enhances Picking Efficiency

Inventory software brings a suite of powerful features to streamline and optimize the picking process in your warehouse. Here’s how it can transform your operations:

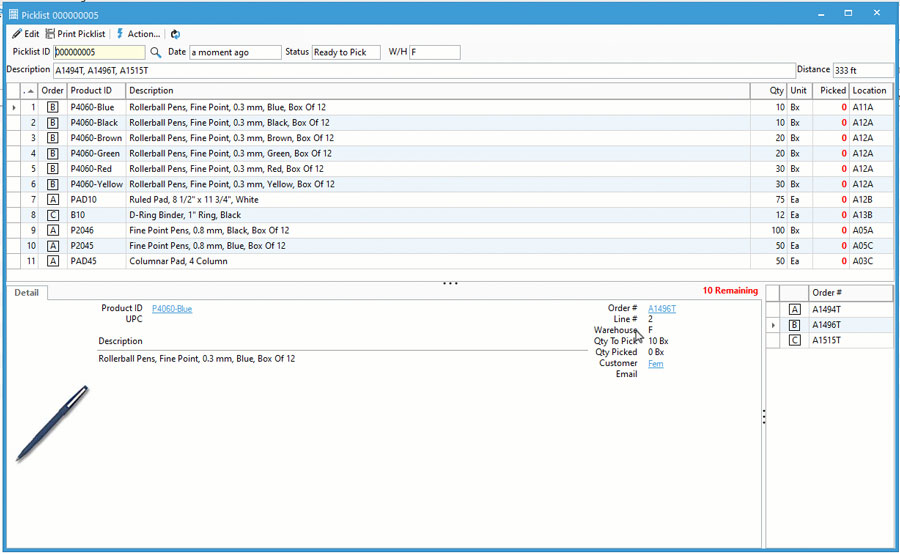

Automated Task Allocation

- Efficient Task Assignment: Inventory software automatically assigns picking tasks to warehouse workers based on real-time data, ensuring that the right person handles the right task at the right time. This reduces downtime and maximizes productivity.

- Prioritization and Scheduling: The software can prioritize urgent orders and schedule tasks to balance the workload among staff, ensuring timely order fulfillment.

Optimized Picking Paths

- Route Optimization: Inventory software calculates the most efficient picking paths, minimizing the distance workers need to travel. This speeds up the picking process and reduces fatigue.

- Batch Picking, where multiple orders are picked in a single trip by grouping similar orders together, further enhances efficiency.

Real-Time Inventory Tracking

- Accurate Stock Levels: Real-time inventory tracking ensures that the system always reflects the most current stock levels, reducing the likelihood of picking errors due to stock discrepancies.

- Instant Updates: As items are picked, inventory levels are updated instantly, maintaining accurate records and improving overall inventory management.

Integration with Barcode Technology

- Speed and Accuracy: Scanning barcodes quickly verifies that the correct items are picked, reducing errors and speeding up the process.

- Ease of Use: Handheld scanners and mobile devices integrated with inventory software make it easy for workers to scan items on the go, ensuring a seamless picking process.

Customizable Dashboards and Reports

- Performance Monitoring: Customizable dashboards provide real-time insights into picking performance, allowing managers to monitor key metrics and identify bottlenecks.

- Data-Driven Decisions: The software generates detailed reports that help analyze trends and make informed decisions to improve the picking process further.

Benefits of Improved Picking Efficiency

By leveraging these features, inventory software enhances picking efficiency, leading to numerous benefits:

- Increased Order Accuracy: Reduced errors mean more accurate orders and higher customer satisfaction.

- Faster Order Fulfillment Times: Optimized paths and automated processes speed up picking, reducing cycle times.

- Reduced Labor Costs: Efficient task allocation and route optimization lower the need for excessive labor, cutting operational costs.

- Improved Customer Satisfaction: More accurate and faster order fulfillment boosts customer satisfaction and loyalty.

Implementing inventory software is a game-changer for improving picking efficiency. It provides the tools to overcome traditional picking challenges and ensures a smoother, more effective operation.

Call us at 817-870-1311