What are Some Tips for Tracking Inventory?

Built For

- Understanding your business needs

- Implementing technology solutions

- Establishing a systematic approach

- Compliance and staying in control of stock & finances

- Training and team involvement

What are Some Tips for Tracking Inventory?

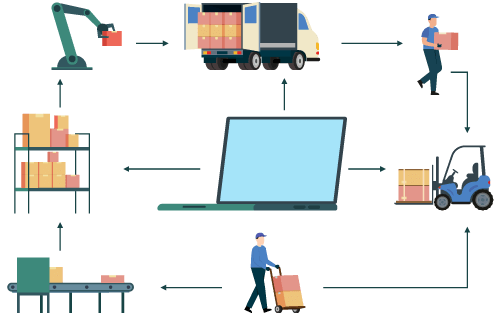

Let’s face it: managing inventory can be like trying to solve a giant puzzle, especially when you’re dealing with everything from last-minute orders to suppliers running behind. However, it’s a huge part of keeping your business’s gears turning smoothly.

Unfortunately, it’s also one of those areas where things can go sideways fast—items get misplaced, numbers don’t add up, and before you know it, you’re either overstocked or scrambling to fill shelves. This is why nailing your inventory tracking isn’t just helpful; it’s essential to dodging significant headaches down the line.

In this guide, we’ll dive into some top-notch tips that can help you keep track of your inventory like a pro. We’ll talk about the latest tech that can make your life easier, how to get your team on board, and strategies to ensure that what you see on your system is what’s actually on your shelves. Ready to get your inventory under control? Let’s get started!

Tracking Inventory Tip #1: Understanding Your Needs

Every business is unique, and so is its inventory. Before diving into the world of inventory tracking, it’s crucial to take a step back and understand what you need from a tracking system.

Are you a small online business with a high turnover of unique items or a manufacturer dealing with hundreds of parts? The scale and complexity of your inventory will dictate the type of tracking system that’s best for you.

Assess Your Inventory

Start by categorizing your inventory. Do you deal mostly with perishable goods, seasonal items, or products that require serial numbers? Knowing the types of products you handle helps you select a system that can effectively manage specific details.

Consider Your Growth

Consider not just your needs today but where you see your business in the next five years. Opt for a scalable system. It’s better to grow into a system than outgrow one quickly.

Industry-Specific Needs

Different industries have different requirements. For example, a food service business must track expiration dates and batch numbers, while an auto parts distributor most likely focuses more on types and variants.

By taking the time to understand your business’s unique needs, you can choose an inventory tracking system that fits like a glove and adapts as your business grows. This foundational step is critical to setting up a system that will not only manage your inventory but also improve your operational efficiency.

Tracking Inventory Tip #2: Implementing Technology Solutions

Gone are the days of tracking inventory with pen and paper or struggling with clunky spreadsheets that barely do the job. Modern problems require modern solutions, and fortunately, inventory management software makes inventory tracking a breeze.

Choosing the Right Software

When picking an inventory management software, look for features that match your business needs. Real-time tracking capabilities, easy integration with other systems (like QuickBooks and eCommerce platforms), and user-friendly interfaces are must-haves.

Automating the Process

Automation is your friend. Inventory management software automates tasks with tools like being alerted to reorder low-stock items, updating stock levels across platforms, and generating reports. This saves time and reduces the risk of human error—meaning fewer inventory discrepancies to deal with.

Benefits of Integration

The more integrated your systems are, the smoother your operations will run. Look for software that integrates well with your existing tools. This could mean syncing with your e-commerce platform to automatically adjust inventory as sales happen online or seamlessly integrating with QuickBooks.

Implementing a robust technology solution for inventory management can significantly improve operational efficiency and provide insights that can drive better business decisions. It’s about finding the right tool, setting it up correctly, and making sure your team knows how to use it effectively.

Tracking Inventory Tip #3: Establishing a Systematic Approach

A little structure can go a long way, especially regarding something as crucial as inventory management. Setting up a systematic approach to tracking your inventory can transform what often seems like chaos into a well-oiled machine. Here’s how you can lay down the groundwork:

Standard Operating Procedures (SOPs)

Develop clear and concise SOPs for every aspect of your inventory process. This includes how items are received, stored, tracked, and shipped. Make sure everyone on the team knows these procedures inside and out. It’s all about consistency—when everyone follows the same process, it’s easier to maintain order and spot issues quickly.

Organize Your Space

Organizing your physical space is crucial, whether it’s a warehouse or a storage room. Use labeling systems and consider the layout—place high-turnover items closer to shipping areas to speed up the process. A well-organized space makes it easier to find products and speeds up inventory counts.

Embrace Digital Tools

Even if you’re using software, how you categorize and input data can make a big difference. Ensure your inventory categories make sense for your business and that you use all the features your software offers.

By establishing these systems and routines, you create a reliable infrastructure for your inventory management. This not only streamlines operations but also provides clearer insights into your business’s flow of goods.

Tracking Inventory Tip #4: Regular Audits and Reconciliation

Think of regular inventory audits as your business’s routine check-up—they help ensure everything is as it should be and often catch issues before they become real problems. Regular audits and diligent reconciliation are not just about compliance but about staying in control of your stock and finances. Here’s how to make these practices part of your inventory management routine:

Schedule Regular Audits

Decide on the frequency of your monthly, quarterly, or annual inventory audits and stick to it. These audits can vary from complete physical counts to cycle counting, where you check a subset of inventory in rotation. This helps identify discrepancies and issues without needing a complete shutdown.

Reconciliation Process

After each audit, reconcile your inventory system’s numbers with what you have on hand. This can reveal issues like theft, loss, or administrative errors. It’s crucial to investigate any discrepancies immediately and adjust your records to reflect the actual stock levels.

Use of Technology

Utilize your inventory management software to streamline the audit process. Audit trails and history logs help you track changes and understand where errors occur. Additionally, barcode scanning makes physical counts faster and more accurate.

Addressing Discrepancies

When discrepancies arise—and they will—it’s essential to have a plan in place. Whether it’s extra training for staff who handle stock or revising your storage practices, addressing the root cause is critical to preventing future issues.

Continuous Improvement

Refine your inventory processes using the insights gained from audits. You may find that certain items are consistently problematic or that your storage layout isn’t as efficient as it could be. Audits can be a great source of operational insights, not just a compliance tool.

By incorporating regular audits and thorough reconciliation processes into your inventory management strategy, you ensure that your business maintains accurate records and operates efficiently. It’s about creating a culture of transparency and accountability that can save you time, money, and headaches in the long run.

Tracking Inventory Tip #5: Training and Team Involvement

An inventory system is only as good as the people using it. Your entire team must be on board and well-trained to get the most out of any inventory tracking method. Engaging your team helps in smoother day-to-day operations and fosters a culture of accountability and precision. Here’s how to effectively involve and train your team:

Comprehensive Training

Ensure every team member who interacts with your inventory system is trained on how to use the software and the importance of accurate tracking. Include practical exercises that mimic daily tasks and common scenarios they might encounter.

Continuous Learning

Inventory management practices and technologies evolve, so keep your team updated with regular training sessions. This could include new features in your software, changes in your operational procedures, or new compliance regulations.

Empowering Your Team

Give team members specific responsibilities related to inventory management. For instance, one person might be in charge of overseeing audits while another handles data entry. Empower them with the authority to address minor issues they discover before these escalate into more significant problems.

Feedback Loop

Establish a feedback loop where team members can report difficulties or suggest improvements to the inventory process. This helps identify areas for improvement and makes team members feel valued and involved in the business’s success.

Reward Accuracy: Consider implementing incentives to maintain accurate inventory records. Recognizing team members who excel in this area can motivate others to pay close attention to detail.

By investing in your team’s training and involving them in the inventory management process, you build a knowledgeable workforce that can effectively handle your business’s inventory needs. This leads to fewer mistakes, quicker problem resolution, and a more cohesive operational flow.

Tracking Inventory Tips FAQs

Why is regular inventory tracking important for businesses?

Regular inventory tracking helps prevent stockouts and overstock situations, reduces the chances of theft and loss, and ensures that records are accurate. This leads to better customer service and more efficient business operations.

What type of inventory management software should I choose?

Choose inventory management software that suits your business’s specific needs, including features like real-time tracking, integration with QuickBooks, and an interface that your team can easily use.

How often should I conduct inventory audits?

The frequency of inventory audits can depend on the volume of your stock and how quickly it turns over. Standard practices include annual, quarterly, or monthly audits. Implementing a cycle counting system where inventory is checked in rotation throughout the year can be especially effective for dynamic businesses.

What are some tips for training staff on inventory management?

Provide comprehensive training on the use of inventory management software and the manual aspects of inventory control. Regularly update training to include new features and practices and empower staff by assigning specific inventory-related responsibilities.

How can I improve inventory accuracy?

Improve inventory accuracy by implementing systematic approaches to tracking, conducting regular audits and reconciliations, using technology effectively, and ensuring that all team members are trained and accountable.

Call us at 817-870-1311