What is the Order Cycle?

Built For

Brad Bearden, Product Manager of Acctivate inventory software delves into the nuances of the order cycle, revealing strategies to optimize it for exceptional customer experiences.

Behind the scenes of any order—online or offline—the buyer’s shopping experience is heavily influenced by a process known as the order cycle.

Whether you’re a retail giant fulfilling thousands of orders daily or a small business catering to a niche market, the order cycle forms the backbone of your operations. It’s the journey your customer’s order takes from when it’s placed to when it’s delivered.

In this article, we’ll explore the intricacies of the order cycle, unraveling its stages, exploring the factors that influence it, and discussing strategies to optimize it. So, grab your coffee, settle in, and let’s demystify the order cycle together.

What is the Order Cycle?

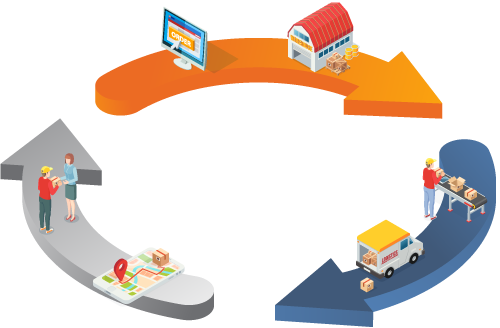

At its core, the order cycle is the heartbeat of any business selling products. It transforms a customer’s request into a tangible delivery, encompassing every step from order placement to delivery.

The order cycle begins when a customer places an order and continues through the various processing, fulfillment, and delivery stages until the ordered items are in the customer’s hands.

Key Components

- Order Placement marks the starting point of the order cycle. Whether clicking “checkout” on an e-commerce website or submitting a purchase order to a supplier, the customer initiates the process by expressing their intent to buy.

- Order Processing: Once an order is received, it undergoes a series of backend operations, including reviewing the order details, verifying inventory availability, and preparing it for fulfillment. Order processing aims to ensure accuracy and efficiency in fulfilling customer requests.

- Order Fulfillment: This stage involves physically picking, packing, and shipping the items ordered by the customer. Whether retrieving products from a warehouse shelf or assembling components for a custom order, order fulfillment is about turning the order into a tangible package ready for shipment.

- Delivery: The final leg of the order cycle is getting the ordered items into the hands of the customer. This may involve coordinating with shipping carriers, arranging transportation, and providing tracking information to inform the customer about their order’s progress.

A smooth order cycle is essential for several reasons:

- It directly impacts customer satisfaction. Delays, errors, or inefficiencies at any stage can result in a poor customer experience.

- An optimized order cycle enhances operational efficiency, reducing costs and maximizing resources.

- It fosters trust and loyalty, encouraging repeat business and positive word-of-mouth recommendations.

In essence, the order cycle is the engine that drives the seamless flow of goods and services from seller to buyer, ensuring satisfaction on both ends of the transaction. Understanding its intricacies is vital to mastering the art of modern commerce.

Factors Affecting the Order Cycle

Many factors influence the order cycle, from inventory management to the dynamics of supplier relationships and managing these factors is vital for ensuring a smooth and efficient order cycle.

Inventory Management

- Inventory Levels: Inventory on hand directly impacts the order cycle. Insufficient inventory may lead to stockouts, delaying order fulfillment, while excess inventory ties up capital and storage space.

- Inventory Accuracy: Accurate inventory records are essential for efficient order processing. Inaccuracies, such as physical and recorded inventory discrepancies, can lead to fulfillment errors and delays.

Supplier Relationships

- Supplier Lead Times: The time it takes for suppliers to deliver goods or materials impacts the order cycle. Longer lead times may necessitate proactive inventory management strategies to avoid stockouts.

- Communication and Collaboration: Strong communication channels and collaborative relationships with suppliers are essential for timely order fulfillment. Clear expectations and effective coordination minimize delays and errors.

Technology and Automation

- Inventory and Order Management Systems streamline order processing, from order placement to fulfillment. Automation reduces manual errors and enhances processes, improving overall efficiency.

- Barcode Technology enhances inventory visibility and accuracy, enabling real-time tracking and management of products throughout the order cycle.

Demand Variability

- Seasonality and Trends: Fluctuations in customer demand due to seasonal trends or market dynamics can impact the order cycle. Anticipating and planning for these fluctuations through data analysis and forecasting minimizes disruptions.

- Promotions and Special Events: Sales promotions, holidays, or special events can lead to sudden spikes in demand. Preparedness and agility in responding to these events are crucial for meeting customer expectations.

Navigating these factors requires a balanced approach, combining proactive planning, effective communication, and leveraging technology to optimize the order cycle. By addressing these key factors, businesses can enhance their agility, responsiveness, and customer satisfaction.

Challenges in the Order Cycle

While the order cycle is designed to facilitate smooth and efficient order processing, various challenges can disrupt its flow. Identifying and addressing these challenges is critical for minimizing delays, errors, and customer dissatisfaction.

Logistics Issues

- Shipping Delays: Delays in transportation or logistics networks can prolong delivery times, impacting the overall order cycle. Weather-related disruptions, congestion in transit routes, or logistical bottlenecks can all contribute to shipping delays.

- Inventory Management Challenges: Inadequate inventory management practices, such as inaccurate forecasting or inefficient replenishment processes, can lead to stockouts or overstocking. These issues disrupt the order cycle, resulting in missed sales opportunities or excess inventory costs.

Communication Breakdowns

- Internal Communication: Poor communication between departments involved in the order cycle, such as sales, inventory management, and fulfillment, can lead to misunderstandings, errors, and delays. Clear and effective communication channels ensure smooth order processing.

- Customer Communication: Inaccurate or insufficient communication with customers regarding order status, shipping updates, or delivery expectations can result in frustration and dissatisfaction. Centralized order management for all sales channels ensures up-to-date information is available for timely and transparent customer communication.

Inventory Management

- Stockouts and Overstocking: Stockouts occur when demand exceeds available inventory, leading to unfulfilled orders and disappointed customers. On the other hand, overstocking ties up capital and warehouse space, increasing carrying costs and the risk of obsolescence.

- Inventory Accuracy: Inaccurate inventory records, caused by discrepancies between physical inventory and recorded quantities, can lead to fulfillment errors, stockouts, and delays. Regular inventory audits and reconciliation are essential for maintaining accurate inventory data.

Customer Expectations

- Expectations for Speed and Convenience: In today’s fast-paced digital landscape, customers expect fast, convenient, and transparent order fulfillment processes. Not meeting these expectations can result in negative reviews, decreased customer loyalty, and lost business.

- Demand for Personalization: Increasingly, customers expect personalized shopping experiences tailored to their preferences and needs. Meeting these expectations requires sophisticated data analysis, inventory management, and advanced order processing capabilities.

A proactive approach, leveraging inventory and order management software, streamlining processes, and fostering a culture of collaboration and continuous improvement addresses many of these challenges. By tackling these obstacles head-on, businesses enhance their order cycle efficiency, improve customer satisfaction, and maintain a competitive edge in the marketplace.

Optimizing the Order Cycle with Inventory and Order Management Software

Leveraging technology is essential for streamlining and optimizing the order cycle. Inventory and order management software is pivotal in enhancing efficiency, accuracy, and responsiveness throughout the order fulfillment process.

Efficient Order Processing

- Centralized Data Management: Inventory and order management software centralizes all relevant data, including product information, customer orders, and inventory levels. This centralized repository ensures that all departments have access to accurate and up-to-date information, minimizing errors and delays in order processing.

- Automated Workflows: Repetitive tasks, such as order entry and workflows, including order verification, picking, packing, and shipping, are optimized with inventory and order management software. By eliminating manual processes, businesses reduce the risk of errors, accelerate order processing times, and improve overall efficiency.

Real-Time Inventory Visibility

- Inventory Tracking: Inventory management software provides real-time visibility into inventory levels, locations, and movements across multiple warehouses or fulfillment centers. This visibility enables businesses to optimize stock levels, anticipate demand fluctuations, and prevent stockouts or overstocking.

- Inventory Optimization: Advanced algorithms and predictive analytics help companies optimize their inventory levels based on historical sales data, seasonality, and market trends. Businesses can minimize carrying costs, maximize inventory turnover, and improve cash flow by maintaining optimal stock levels.

Streamlined Order Fulfillment

- Optimized Picking and Packing: Inventory and order management software paired with barcode technology optimizes picking, packing and shipping, ensuring faster and more accurate order fulfillment.

- Integration with Shipping Carriers: Seamless integration with shipping carriers allows businesses to generate shipping labels and track shipments directly within the software interface. Integration streamlines the shipping process, reduces manual errors, and improves delivery accuracy.

Enhanced Customer Experience

- Order Tracking and Notifications: Inventory and order management software enables businesses to provide customers real-time order tracking and status updates. Transparent communication and proactive updates enhance the customer experience, reduce inquiries, and build trust and loyalty.

- Personalization: Inventory management software tracks customer purchase history and preferences, serving as a repository for customer purchasing history and preferences and providing information for sales teams and customer service representatives to enhance engagement, encourage repeat purchases, and drive customer satisfaction and loyalty.

Inventory and order management software is a powerful tool for optimizing the order cycle, from order placement to delivery. By streamlining processes, providing real-time visibility into inventory, and enhancing the customer experience, these software solutions empower businesses to improve efficiency, reduce costs, and stay competitive in today’s dynamic marketplace.

Frequently Asked Questions (FAQs) About the Order Cycle

What is the typical duration of an order cycle?

The duration of an order cycle can vary depending on factors such as industry, product type, and order volume. In industries with fast-moving consumer goods and efficient logistics networks, order cycles may be measured in days or even hours. Conversely, in sectors with complex supply chains or custom-made products, they may span weeks or months.

How can businesses minimize order cycle times?

Businesses can minimize order cycle times by implementing efficient processes, leveraging technology, and optimizing inventory management practices. This includes streamlining order processing workflows, investing in inventory and order management software, maintaining optimal inventory levels, and collaborating closely with suppliers and shipping partners to reduce lead times.

What are the consequences of delays in the order cycle?

Delays in the order cycle can significantly affect businesses and their customers. For businesses, delays can result in increased operating costs, excess inventory holding costs, lost sales opportunities, and damage to reputation. For customers, delays can lead to frustration, dissatisfaction, and a loss of trust in the brand, potentially driving them to seek alternatives.

How can businesses handle unexpected fluctuations in demand within the order cycle?

Businesses can prepare for unexpected fluctuations in demand by adopting agile and flexible supply chain strategies. These include maintaining buffer inventory to accommodate sudden spikes in demand, implementing dynamic pricing mechanisms to manage demand surges, and fostering strong relationships with suppliers to ensure rapid stock replenishment. Additionally, leveraging data analytics and forecasting tools can help businesses proactively anticipate and respond to demand fluctuations.

What role does communication play in the order cycle?

Communication is critical in the order cycle, both externally and internally, with partners, suppliers, and customers. Effective communication ensures all stakeholders are aligned, processes run smoothly, and customers are informed about their orders’ status. Clear and transparent communication builds trust, minimizes errors, and enhances the customer experience throughout the order cycle.

Call us at 817-870-1311