How to Achieve Faster Inventory Turns

Built For

How to Achieve Faster Inventory Turns

Managing inventory efficiently is crucial for keeping operations smooth and profits up. One key metric to keep an eye on is your inventory turnover ratio, often called inventory turns.

Inventory turns show how often inventory is sold and replaced over a specific period.

In simpler terms, it provides insight as to how quickly you move products off the shelves and make room for new ones. Faster inventory turns mean you’re selling your stock more quickly, which brings many benefits, like better cash flow, lower storage costs, and the ability to respond swiftly to market changes.

In this article, we’ll delve into what inventory turns are all about, why they matter, and share some tips to help you speed up your inventory turnover. By fine-tuning your inventory management, you can boost your efficiency and increase your profits. Let’s get started!

Understanding Inventory Turns

Inventory turnover ratio, or inventory turns, is a key performance metric that indicates how many times over a specific period inventory is sold and replaced. It measures how efficiently a business manages its inventory. A higher turnover rate generally signifies efficient inventory management, while a lower rate may indicate overstocking or sluggish sales.

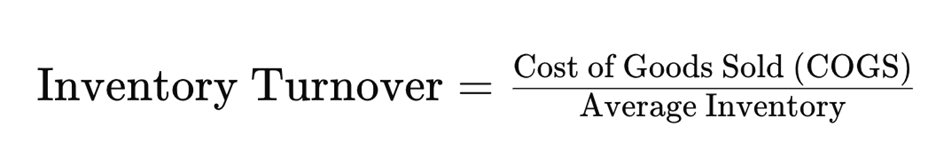

Formula to Calculate Inventory Turnover

- Cost of Goods Sold (COGS): The direct costs attributable to the goods sold by a company.

- Average Inventory: This is calculated by adding the beginning inventory and ending inventory for a period and then dividing by two.

For example, if a business sold $100,000 worth of inventory this year (COGS) and, on average, had $25,000 worth of inventory waiting to be sold to customers (average inventory), its inventory turnover rate would be $100,000 divided by $25,000, or 4.0—the inventory was sold and restocked four times over the year.

By understanding and monitoring your inventory turnover, you gain insight into the effectiveness of your inventory management system and make informed decisions to optimize your operations. In the next section, we’ll explore into the numerous benefits of achieving faster inventory turns.

Benefits of Faster Inventory Turns

Achieving faster inventory turns can have a significant positive impact on your business. Here are some key benefits:

Improved Cash Flow

When your inventory moves quickly, you free up cash that can be reinvested in other business areas. Instead of having funds tied up in unsold stock, you can use that money to purchase new inventory, expand your product line, or invest in marketing and growth initiatives. Faster inventory turns mean more frequent sales, translating to more consistent cash flow.

Reducing Holding Costs

Holding costs, also known as carrying costs, include expenses related to storing unsold inventory, such as warehousing, insurance, and depreciation. The longer an item sits in your inventory, the more it costs. Turning over your inventory faster minimizes these costs, ultimately improving your profit margins.

Increased Responsiveness to Market Changes

Consumer preferences and trends can change rapidly. Faster inventory turns allow you to stay agile and responsive to these changes. Regularly refreshing your inventory can better align your product offerings with current demand, reducing the risk of obsolescence and markdowns.

Enhanced Profitability

Higher inventory turnover often leads to higher profitability. When you sell products quickly, you can take advantage of negotiate better terms with suppliers and bulk purchasing discounts. Additionally, fast-moving inventory tends to generate more sales, leading to increased revenue. Lower holding costs and more efficient use of capital also contribute to improved profitability.

Better Inventory Management

Achieving faster inventory turns typically requires you to implement more efficient inventory management practices, which can lead to more accurate demand forecasting, optimized stock levels, and improved order fulfillment processes. By focusing on inventory turnover, you naturally develop a more disciplined and streamlined approach to managing your stock.

Improved Customer Satisfaction

When you maintain an efficient inventory turnover rate, customers are more likely to find what they need. Faster inventory turns mean that your shelves are always stocked with fresh, in-demand products, reducing the likelihood of stockouts and backorders. This leads to happier customers and can enhance your reputation and customer loyalty.

Faster inventory turns offer many benefits that can strengthen your business’s financial health, operational efficiency, and customer satisfaction.

Strategies to Achieve Faster Inventory Turns

Achieving faster inventory turns requires smart planning, efficient processes, and effective use of technology. Here are some strategies to help you get there:

Accurate Demand Forecasting

One of the most crucial steps in achieving faster inventory turns is accurately predicting customer demand. Understanding what products your customers are likely to buy and when ensures you have the right amount of inventory. Here’s how you can improve your demand forecasting:

- Historical Data Analysis: Use sales data to identify sales trends and patterns. This will help you anticipate future demand more accurately.

- Market Trends: Stay up-to-date on consumer behavior and market trends. This includes seasonal trends, economic indicators, and industry news.

- Inventory Software: Inventory management software provides real-time insights and analytics for your entire business, helping you make data-driven decisions and improve forecasting accuracy.

Optimizing Inventory Levels

Maintaining optimal inventory levels is vital to avoiding both overstocking and stockouts. Here are some techniques to help you optimize your inventory:

- Just-In-Time (JIT) Inventory: Adopt JIT inventory management to reduce excess stock. With JIT, you order inventory just in time to meet demand, minimizing holding costs.

- Safety Stock: Determine the appropriate safety stock level to buffer against unexpected demand spikes or supply chain disruptions.

- ABC Analysis: Classify inventory into three categories (A, B, C) based on importance and turnover rates. Focus on more closely managing A items (high value, fast-moving).

Streamlining Order Management Processes

Efficient order processing can significantly speed up your inventory turnover. Here are some ways to streamline your order management:

- Automated Order Processing: Inventory and order systems handle order processing and fulfillment, reducing errors and speeding up the workflow.

- Barcode Systems: Implement barcode systems to quickly and accurately track inventory movement. This improves order accuracy and fulfillment speed.

- Order Management Systems: Inventory software with order management capabilities ensures seamless coordination between sales and inventory.

Improving Supplier Relationships

Strong relationships with your suppliers can help you achieve faster inventory turns by ensuring timely and reliable delivery of goods. Here’s how to improve supplier relationships:

- Reliable Suppliers: Use information from you inventory system to monitor supplier performance and partner with reliable suppliers who consistently deliver on time and meet quality standards.

- Collaborative Planning: Work closely with suppliers on demand forecasting and inventory planning. This ensures that your supply chain is aligned with your business needs.

- Negotiation: To improve your inventory turnover, negotiate favorable terms, such as shorter lead times and flexible payment options.

Enhancing Warehouse Efficiency

Efficient warehouse operations play a role in moving inventory quickly. Here are some strategies to enhance warehouse efficiency:

- Layout Optimization: Design your warehouse layout to minimize movement and maximize efficiency. Place high-turnover items in easily accessible locations.

- Regular Cycle Counts: Conduct regular cycle counts to ensure inventory accuracy and reduce discrepancies. This helps in maintaining optimal stock levels.

Continuous Improvement

Effective inventory management focuses on minimizing waste and maximizing efficiency. Consider implementing:

- Value Stream Mapping: Analyze and map out all the steps in your inventory process to identify and eliminate waste.

- Continuous Improvement: Foster a culture where employees regularly suggest and implement process improvements.

Implementing these strategies can lead to faster inventory turns, improved cash flow, reduced costs, and enhanced overall business performance.

Call us at 817-870-1311