What is Obsolete Inventory?

Built For

This article discusses obsolete inventory, from its causes, challenges to how to easily conquer it.

What is Obsolete Inventory?

So, picture this: you’re excited about the new phone model you just bought, but your old phone is buried in a drawer somewhere, now relegated to the tech graveyard. In the business world, that old phone is known as obsolete inventory. It’s the stuff companies have hanging around that’s about as in-demand as a flip phone at a smartphone convention.

Obsolete inventory is a collection of products that have overstayed their welcome on the warehouse shelves and are now collecting dust. Why does this happen? Maybe a newer, shinier version has hit the market, or perhaps the fickle winds of consumer taste have shifted direction. Whatever the reason, these items are now the wallflowers of the inventory world.

Obsolete inventory can be a real headache for businesses. It ties up cash, takes up space, and can be a bit of an accounting thorn in the side. Ignoring it is like hoping the expired milk in your fridge will somehow become fresh again—it just won’t happen.

In the following paragraphs, we’ll explore the ins and outs of obsolete inventory. We’ll uncover how it sneaks up on businesses, the trouble it can cause, and, most importantly, how to handle it without breaking into a sweat. So, let’s dive in and demystify the dusty corners of inventory management, shall we?

Understanding Obsolete Inventory

Obsolete inventory typically has not gone bad or is broken; it’s just that no one needs or uses it now. Obsolete inventory is the stuff that newer, shinier models have surpassed or fallen out of favor with the cool crowd. This inventory isn’t necessarily defective; it’s just no longer relevant.

Technological Advancements

In the tech world, the only constant is change. Thanks to the relentless march of technology, yesterday’s cutting-edge smartphone is today’s paperweight. This isn’t limited to electronics; advancements in materials, design, and functionality constantly push older products out of the spotlight and into the obsolete bin.

Changing Consumer Preferences

Tastes change, and what’s in vogue one day can be passé the next. Whether it’s fashion, food, or furniture, consumer demand can be as unpredictable as the weather, turning hot items into not-so-hot with the shift of societal winds. This fickleness can transform perfectly good inventory into wallflowers no one wants to dance with.

Seasonal and Fashion Trends

Some products have a shelf life dictated by the calendar. Think holiday decorations or seasonal clothing lines; these items have a ticking clock attached, making them highly susceptible to becoming obsolete once the season passes or the trend fades.

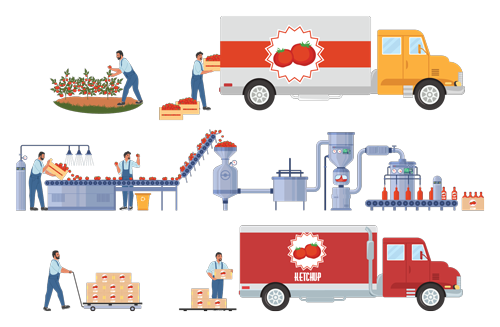

Product Expiration and Shelf-Life

For certain goods, like pharmaceuticals and food, the expiration date is a literal countdown to obsolescence. These products can’t be sold or safely used past their ‘best by’ dates, turning them into instant candidates for the obsolete inventory list.

Regulatory Changes

Sometimes, what makes an item obsolete isn’t about what’s trendy or technological—it’s about compliance. New laws or regulations can suddenly render a product unfit for sale or use, pushing it into obsolescence regardless of its popularity or utility.

Identifying Obsolete Inventory

Just like having a map won’t help if you don’t know where you are, understanding that obsolete inventory exists is one thing; spotting it is another. Enter inventory management software—your high-tech compass in the vast wilderness of stockkeeping. This digital tool doesn’t just track what you have; it shines a spotlight on what’s gathering dust.

Inventory Management Software – The Digital Detective

Think of inventory management software as your Sherlock Holmes in warehouses and stockrooms. It scours through data, looking for clues like slow sales, stock age, and the last time an item danced off the shelves. This software doesn’t miss a beat, flagging items slowing down and risking obsolescence.

Sales and Inventory Turnover Rates

Inventory management software keeps a keen eye on sales and inventory turnover rates. The software notes whether an item isn’t flying off the shelves as it used to. It’s like having a heart monitor for your products; when the heartbeat slows, it’s a sign that the product might be heading toward the obsolete inventory pile.

Market Trends and Product Lifecycle Stages

Staying ahead of trends is crucial. Inventory software predicts which items will likely become obsolete by analyzing sales data and market trends. It considers your products’ lifecycle stages, warning you when an item is moving from maturity to decline and giving you a heads-up to take action.

Regular Inventory Audits

Scheduled health check-ups help us stay in tip-top shape; the same goes for your inventory. Inventory management software automates the process of regular audits, systematically reviewing stock to ensure everything is selling as expected. Items that linger too long without movement are marked for review, helping you identify potential obsolescence before it becomes problematic.

Forecasting

Finally, inventory management software’s demand forecasting tools help you make informed decisions about restocking. If the forecast shows dwindling demand, it’s a red flag that a product may soon become obsolete. This insight lets you adjust purchasing orders and marketing strategies, staying one step ahead.

Strategies for Managing Obsolete Inventory

Discovering a pile of obsolete inventory might feel like finding a closet full of last season’s fashion—slightly disappointing and a tad overwhelming. But don’t fret! There are plenty of savvy strategies to turn this situation around. You can minimize losses and free up some warehouse space with the right moves.

- Discounting and Clearance Sales: The most straightforward approach is to slash those prices and get the word out. Clearance sales and discounts can attract bargain hunters and clear out old stock. It’s like hosting a farewell party for last season’s items—everyone’s invited, and everything must go!

- Bundle Deals: Sometimes, the best way to move old inventory is to pair it with something more desirable. Bundle that obsolete inventory with best-sellers at a tempting price. It’s like making a new friend more popular by introducing them to your cool circle—suddenly, everyone’s interested.

- Donating obsolete inventory can be a win-win if selling doesn’t cut it. You clear your storage space and reduce carrying costs, support a good cause, and potentially receive a tax deduction.

- Recycling and Upcycling: Consider recycling or upcycling items that can’t be sold or donated. This approach is not just environmentally friendly; it can also be creatively rewarding. Whether it’s turning outdated fashion into designer patches or repurposing old tech, there are possibilities to explore.

- Return to Suppliers or Manufacturers: Sometimes, you can return unsold items to the manufacturer or supplied for a refund or credit toward future purchases. This requires negotiation and a good relationship with your suppliers, but it can effectively reduce losses from obsolete inventory.

- Liquidation Companies: When all else fails, liquidation companies can take obsolete inventory off your hands. While you won’t recoup all your costs, it’s a way to recover some value and focus on the future.

What is Obsolete Inventory? FAQs

What is obsolete inventory?

Obsolete inventory refers to items no longer sellable due to their lack of relevance, demand, or functionality in the current market. These can be products that newer models have surpassed, are out of fashion, or have reached their expiration date.

How does obsolete inventory affect a business?

Obsolete inventory ties up capital that could be used more effectively elsewhere and incurs additional storage, insurance, and management costs. It can also impact a business’s operational efficiency and profitability.

Can obsolete inventory be prevented?

While it’s challenging to entirely eliminate obsolete inventory, businesses can significantly reduce its occurrence through strategies like improved demand forecasting and regularly reviewing product lines and sales data.

What should a company consider before deciding to liquidate obsolete inventory?

Before liquidating, companies should consider the potential recovery value, the impact on brand image, and the costs associated with the liquidation process. It’s also essential to explore all other options, such as discounts, donations, and returns to suppliers, as liquidation typically offers the lowest return.

Call us at 817-870-1311