Why is Traceability Important?

Built For

- The role of traceability

- Traceability in supply chain management

- Traceability and consumer confidence

- Inventory software for traceability

Why is Traceability Important?

Have you ever had a food item recalled that you bought months ago? You’re dealing with traceability. Traceability is like the breadcrumb trail that helps us retrace the path of an item back through its journey from creation to end-use. It’s crucial, whether we’re talking about the auto parts that keep our cars safely on the road, the components in our electronic devices, or the food on our plates.

But why is it such a big deal? Well, traceability ensures that the parts we use, the products we consume, and pretty much everything in between meet the mustard when it comes to quality and safety. It’s all about pinpointing where something came from, where it’s been, and where it’s going next or ended up. And in a world that’s moving a mile a minute, keeping track of all this is no small feat.

From an airplane’s critical components to the humble nuts and bolts holding your bookshelf together, traceability is not just about accountability—it’s about peace of mind. Knowing that a part or a food item can be traced back to its origin means we can quickly nip issues in the bud if something goes awry. It’s also about standing tall and transparent in front of regulatory bodies that rightly demand to know the who, what, and where of parts in industries across the board.

In today’s article, we’ll discover why traceability is not just a fancy term companies throw around but an essential aspect of our everyday lives that keeps the wheels turning.

The Role of Traceability

Think of traceability as the ultimate behind-the-scenes documentary of everything that goes into the products we use and consume daily. It’s a story that, while not always glamorous, is fundamentally important for a variety of reasons.

Ensuring Quality and Safety

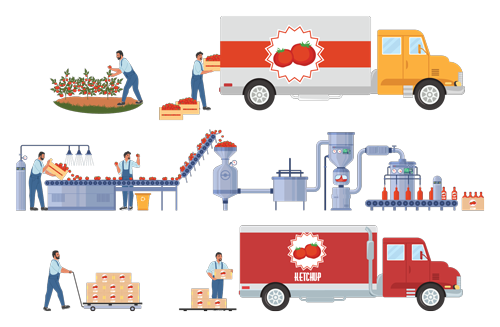

For starters, traceability is like the guardian of quality and safety. Let’s talk food: from farm to fork, tracking the journey of an apple ensures that if it’s part of a bad batch, the rest can be quickly pulled from shelves, keeping tummy aches at bay. In the world of parts, it’s not just about preventing an oops moment; it’s about averting potential disasters. Imagine tracing a faulty car brake pad before it led to an accident. That’s the power of traceability—prevention.

Regulatory Compliance

Governments and industries love their regulations—and for good reasons. Traceability keeps companies in line with these standards. If a food item causes an illness, traceability helps identify the source and enforce food safety laws. For parts, it’s about meeting quality standards and ensuring that every piece in a machine meets rigorous specifications. And if something doesn’t add up, traceability provides the paper trail needed to address it legally.

Recalls and Liability

No one likes a recall, but they’re essential for safety. Traceability streamlines the recall process, whether it’s contaminated spinach or a batch of electronics with a wiring defect. By knowing which products are affected, companies can minimize the impact and cost of a recall. Plus, it’s not just about fixing mistakes; it’s about learning from them and improving future production.

Sustainability and Ethical Practices

More and more consumers are voting with their wallets for products that are not only safe but also ethically and sustainably produced. Traceability allows us to follow the story of a product back to its roots. Did those coffee beans come from a farm that pays fair wages? Were those car parts made in a factory that practices environmental stewardship? Traceability is critical to answering these questions and upholding ethical standards.

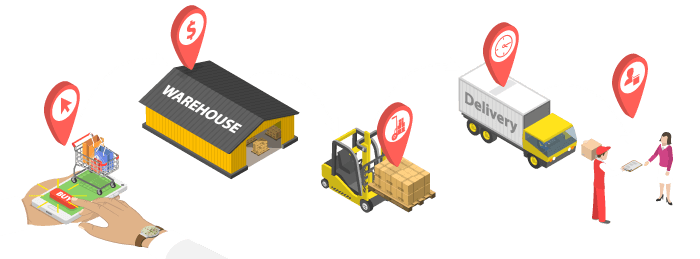

Traceability in Supply Chain Management

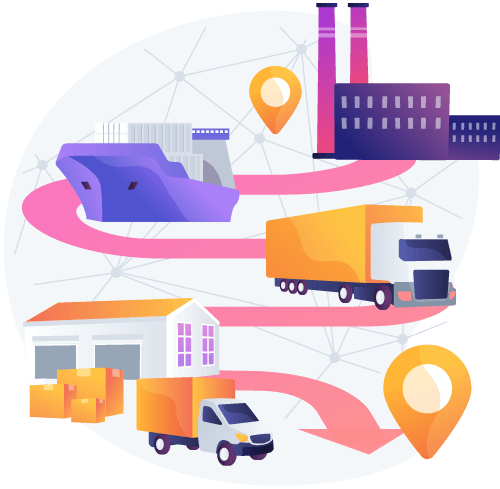

If the supply chain is the river that carries products to their destination, then traceability is the navigator that ensures they don’t stray off course. It’s an integral part of managing the flow from start to finish, and here’s why it’s making waves.

Enhancing Visibility and Accountability

Visibility is the holy grail in supply chain management. With traceability, companies can see the whole picture of a product’s journey, not just a snapshot. It’s about connecting the dots from the manufacturer or producer to the end-user. In the world of parts, this means tracking the component from the forge to the factory to the family car. For food, it’s about following the trail from seed to supermarket to salad bowl. This comprehensive view empowers companies to make informed decisions and take responsibility for their supply chain.

Mitigating Risks

Let’s face it: Risks lurk around every corner of the supply chain. A storm can delay shipments, a factory fault can contaminate food, and human error can always throw a wrench in the works. Traceability acts as a risk management tool, allowing companies to identify and resolve issues and escalate quickly. It’s the difference between a controlled response and a full-blown crisis.

Increasing Efficiency and Reducing Waste

Efficiency isn’t just about speed; it’s about intelligent movement. Traceability provides data that helps streamline operations, predict demand, and reduce excess. It’s about eliminating the guesswork and ensuring the right amount of product arrives at the right place and time. For perishable goods like food, traceability can mean less spoilage and waste.

Strengthening Partnerships

When you can trust the process, you can trust the partner. Traceability builds confidence among stakeholders in the supply chain. Suppliers, manufacturers, distributors, and retailers all benefit from traceability’s transparency. It fosters a spirit of collaboration and mutual accountability, where each link in the chain plays a crucial role in the entire supply chain’s integrity.

Responding to Consumer Demand

In an age where consumers want to know more about the products they buy, traceability provides answers. They can learn about the origin of the auto parts in their vehicle or the journey of the ingredients in their meal. This isn’t just about satisfying curiosity; it’s about responding to a demand for authenticity and responsible sourcing.

Traceability and Consumer Confidence

In a world brimming with choices, trust is the currency that brands and consumers trade in. Traceability is the mint where this currency is coined, and here’s how it builds that invaluable consumer confidence.

Building Trust with End Users

When consumers pick up a product, they’re not just looking at the price tag; they’re looking for reassurance. Traceability provides that by serving as a seal of trust. It tells a story of care and quality that has become increasingly important. Whether it’s ensuring that the parts in their gadgets will work as promised or that the food on their plate is safe and fresh, traceability allows consumers to trust their products.

Enabling Informed Choices

Today’s consumers are more informed than ever before. With smartphones in hand, they can make on-the-spot decisions about what they buy based on the traceability information companies provide. Traceability can reveal whether a product is organic, GMO-free, or sustainably sourced—information that is now often just a QR code scan away. It equips consumers with knowledge, and with knowledge comes the power to make choices aligned with personal values and health considerations.

Responding to Crisis with Confidence

Recalls and safety scares can break a brand, but traceability can help cushion the fall. It allows companies to act swiftly and precisely, targeting the source of the problem without casting a wide net. This responsiveness mitigates the impact of a crisis and demonstrates a commitment to consumer welfare, which can reinforce consumer trust even in challenging times.

Implementing Traceability with Inventory Software

Inventory software plays a pivotal role in implementing traceability and automating processes and reports that were previously manual, tedious, and time-consuming.

Digital Record-Keeping

Gone are the days of pen and paper logs prone to errors and coffee stains. Inventory software digitizes record-keeping, making it easier to track products through unique identifiers like serial numbers and batch codes. This digital ledger is not just more accurate; it’s accessible in real time, allowing for immediate tracing of any item within the system.

Automating Traceability

Manual tracking is labor-intensive and riddled with potential for human error. Inventory software automates the traceability process, ensuring consistency and reliability in the data captured. From the moment raw materials are received to the point where finished goods are shipped, every transaction is recorded without requiring manual input.

Connecting with Suppliers and Partners

Traceability isn’t confined to the walls of a single company; it spans the entire supply chain. Inventory software allows for a seamless flow of traceability data across different entities. This integration ensures that the traceability story is complete and not just a fragmented tale.

Data Analysis and Insights

Inventory software doesn’t just collect data; it turns data into insights. Companies can use this software to analyze patterns, identify bottlenecks, and predict trends. This analysis can lead to more informed decisions, such as optimizing inventory levels to reduce waste or adjusting procurement to better match demand.

Enforcing Accountability

With inventory software, every action is timestamped and attributed to a user, enforcing accountability throughout the supply chain. This clear line of responsibility helps in quickly isolating issues, addressing inefficiencies, and enforcing standards at each stage of the supply chain.

Scalability and Flexibility

As businesses grow, their traceability systems need to keep pace. Inventory software is scalable and can handle increasing data volumes and more complex supply chains. Moreover, it’s flexible and able to adapt to new regulations, market demands, and changes in business processes.

Traceability – A Critical Component of Supply Chains

From food to parts, traceability provides the transparency needed to build consumer trust, manage risks, and increase operational efficiency. Implementing traceability can be streamlined through inventory software, which automates the tracking of products across the supply chain and provides valuable insights for business decisions. By embracing traceability, companies can meet today’s regulatory and ethical demands and pave the way for a more sustainable and accountable future in business practices.

Why is Traceability Important? FAQs

What is traceability in supply chain management?

Traceability in supply chain management refers to the ability to trace an item or activity’s history, application, or location within the supply chain through recorded identification.

Why is traceability important for consumers?

Traceability is essential for consumers, ensuring the products they purchase are safe and authentic and align with their values of sustainability and ethics. It also empowers them to make informed choices about the products they use.

How do inventory software systems improve traceability?

Inventory software systems improve traceability by digitizing the tracking process, automating data capture, enforcing accountability, and providing actionable insights through data analysis.

Can traceability help if there’s a product recall?

Traceability is crucial during a product recall as it allows a company to swiftly identify and isolate affected products, thereby minimizing risk to consumers and reducing the company’s financial and reputational impact.

Are there industries where traceability is more important?

Traceability is particularly vital in industries where safety and compliance are critical, such as food and beverage, pharmaceuticals, automotive, and aerospace. However, it’s increasingly important in all sectors due to rising consumer expectations and regulatory pressures.

Call us at 817-870-1311