What is Warehousing and Distribution?

Built For

What is Warehousing and Distribution?

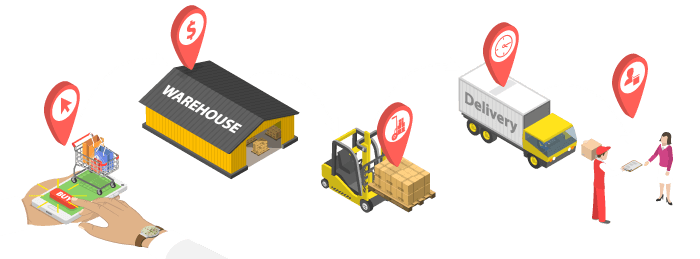

Hey there! Have you ever wondered how that package lands at your doorstep with just a click? Or how stores never seem to run out of your favorite snacks? The secret sauce to the process is a well-oiled machine known as warehousing and distribution. It’s the backbone of supply chains worldwide, ensuring products move seamlessly from point A to point B. But it’s not just about moving boxes; it’s a sophisticated dance involving technology, strategy, and a bit of logistics magic.

At the heart of this dance lies cutting-edge inventory and warehouse management software that enables businesses to keep track of their goods across vast warehouses, ensuring that everything is where it needs to be and when it needs to be there.

In this article, we’ll dive into the nuts and bolts of warehousing and distribution. We’ll explore how these essential functions fit into the larger puzzle of supply chain management and how technology, mainly inventory and warehouse management software, is revolutionizing how businesses store, track, and distribute products.

Warehouses – More Than Just Storage

Welcome to the hidden world of warehouses, the critical spaces where products from around the globe take a pit stop on their journey to your doorstep. It’s a world that’s much more than stacks of boxes and forklifts zipping around—warehousing is a key puzzle piece in the supply chain, ensuring products are safely stored, adequately managed, and ready to roll out at a moment’s notice.

Warehousing Operations and Functions

Imagine a warehouse as a beehive buzzing with activity. Each bee has a role, from storing honey (products) to keeping the hive running smoothly. Similarly, warehouses are hubs of activity where goods are received, stored, and dispatched. Operations also include managing stock levels, picking and packing orders, and ensuring products are stored under optimal conditions to maintain quality. It’s a blend of physical labor and strategic planning, all aimed at keeping the supply chain seamless.

Types of Warehouses

Warehouses come in different flavors, each serving unique needs.

- Public warehouses are open to any business needing storage space, offering flexibility without the long-term commitment.

- Private warehouses are owned by a single business and tailored to its specific requirements—think of them as your personal storage fortress.

- Customs regulations govern bonded warehouses; these are warehouses for imported goods waiting for their clearance papers.

The Role of Inventory and Warehouse Management Software

Now, let’s talk tech—specifically, inventory and warehouse management software that tracks every item in the warehouse, updates stock levels automatically, predicts when stock will run out, and gives businesses the ability to reduce waste, make informed decisions, and improve efficiency.

Integrating inventory and warehouse management software into warehousing isn’t just a trend; it’s a revolution. It’s transforming dusty old storage spaces into dynamic, data-driven environments. The software enables warehouses to operate more efficiently, reduce errors, provide better customer service, and scale up without the growing pains.

The Magic Behind Distribution

Distribution isn’t just about moving goods; it’s about ensuring they reach the right place, at the right time, in the perfect condition.

What Makes Distribution Tick?

At its core, distribution is all about strategy—the art of efficiently moving products from the warehouse to the customer. It involves a series of decisions on transportation or shipping methods and delivery schedules, all while keeping costs down and customers happy.

The Routes We Take: Distribution Strategies

There are several paths products can take on their journey to the consumer, each with its own set of advantages:

- Direct-to-Consumer (D2C): This strategy eliminates the middleman, sending products directly from the manufacturer to the buyer. It’s fast and allows manufacturers to build a direct relationship with their customers.

- Wholesale Distribution: The heavy lifter of bulk transactions, wholesale distribution acts as the intermediary, purchasing goods in massive quantities from producers to supply retailers, other distributors, or large institutional clients.

- Retail distribution: Here, products stop at online or offline stores before reaching consumers.

- Omnichannel distribution is a hybrid approach that blends online and offline channels into a seamless customer experience, regardless of where or how the purchase is made.

Distribution Centers: More Than Just Warehouses — A Small Business Perspective

While the retail giants may have dozens or hundreds of sprawling distribution centers, step into the world of small businesses, and you’ll find warehouse spaces pulling double duty. Not only do warehouses store products, but they also act as nerve centers where inventory, orders, and shipments are managed with precision.

In these hybrid hubs, space might be tighter, but the action is just as intense. Small businesses optimize every square inch, turning their warehouse into a multitasking powerhouse that stores products and dispatches them directly to customers or retail partners. It’s a masterclass in efficiency — imagine a Swiss Army knife but for logistics.

This model keeps things lean and means small businesses can stay nimble, adapting quickly to changes in demand without the overhead of separate facilities. By leveraging intelligent inventory practices and flexible distribution methods, they provide the same level of service as the big players, proving that in the world of distribution, size isn’t everything — it’s how you use it.

Leveraging Technology in Small Business Distribution

For small businesses, technology isn’t just a luxury; it’s the slingshot that levels the playing field with the industry’s Goliaths. In the realm of distribution, small businesses have started to wield technology as a mighty tool to supercharge their operations. Gone are the days when cutting-edge tech was reserved for the big players.

Embracing the Tech Edge

Small businesses now embrace digital tools that offer a buffet of features once thought unattainable. We’re talking about powerful and easy-to-use inventory management systems that offer real-time tracking of shipments and the ability to peek into stock levels from anywhere—be it a beach in Bali or your local coffee shop.

Smart Choices for Limited Spaces

In small business, a warehouse often wears many hats—it’s a storage area, a distribution center, and sometimes, the HQ. Digital solutions allow for seamless integration of these roles, ensuring that even the most compact spaces can function with the efficiency of a sprawling distribution center. By smartly managing inventory and automating order processing, small businesses can punch well above their weight, ensuring that every square foot of their space is used to its maximum potential.

Personalized Customer Experience

Moreover, tech allows small businesses to add a personal touch to the distribution process. With tools to customize order packaging and delivery, inventory and warehouse management software can make every customer feel special, creating an unboxing experience that rivals the joy of receiving a hand-picked gift. It’s about making every delivery a moment to remember; technology is the secret ingredient that makes this possible.

Technology in distribution for small businesses isn’t just about keeping up; it’s about standing out, delivering with precision, and connecting with customers in ways that were once just a dream.

Seamless Symbiosis: Integrating Warehousing and Distribution

The dance between warehousing and distribution is an intimate and precise tango. It’s about making two distinct parts move seamlessly, ensuring the flow from storage to delivery is as smooth as silk. This integration is crucial; one can only thrive with the other, especially in a market where speed and efficiency are kings.

Warehousing Meets Distribution

Think of warehousing and distribution as a dynamic duo. Separately, they’re good, but together, they’re spectacular. Warehouses store the goods, while distribution gets them out into the world. But when these processes are integrated, that’s when the magic happens. A warehouse directly linked to distribution channels can respond faster to orders, reduce handling times, and reduce transportation costs. It’s all about being quick on your feet and ready to leap into action.

Strategic Locations: The Where Matters

Location, location, location—it’s not just a real estate mantra; it’s a pivotal strategy in optimizing warehousing and distribution. Choosing a warehouse location isn’t just about the rent costs; it’s about being close to your customers and suppliers. It’s about finding that sweet spot where transportation costs are minimized and delivery times are zapped. Innovative businesses know that an optimal location is a cornerstone for efficient distribution.

Maximizing Layout and Flow

A well-thought-out warehouse layout is like having the right dance floor for that tango. You want a flow that allows for smooth moves and quick steps. This means designing the space so products can move directly from receiving to shipping with minimal detours. It’s about having the right shelves, the right aisles, and the right storage solutions to ensure that when an order comes in, it can be picked, packed, and shipped without a hitch.

Inventory Management: The Maestro of the Orchestra

At the core of this integration is inventory management—the maestro of the orchestra. It’s what keeps the music playing at the right tempo. A stellar inventory management system gives you visibility across your entire supply chain, alerts you to restock products, and even predicts demand before it happens. For warehousing and distribution, this system ensures that every product is accounted for and every delivery is on point. It’s about having the data at your fingertips to make the decisions that keep customers smiling and the bottom line healthy.

Integrating warehousing and distribution isn’t just about throwing resources together; it’s about creating a symphony where each note and movement is in harmony. It’s how small businesses become giants and how giants stay ahead. It’s the secret to not just surviving but thriving in the fast-paced world of supply chain logistics.

What is Warehousing and Distribution? FAQs

What’s the difference between warehousing and distribution?

Warehousing involves storing goods efficiently, while distribution is the process of getting those goods to the end customer. They’re two sides of the same coin, with warehousing keeping products safe and distribution ensuring they reach their destination.

How do I choose the right location for my warehouse?

The ideal warehouse location balances proximity to your customer base, easy access to transportation networks, and affordability. It’s about being close enough to your market to ensure quick delivery times while managing costs.

Can a warehouse also function as a distribution center?

Absolutely. For many small businesses, the warehouse acts as a storage space and a hub for distribution. The key is integrating inventory management and streamlining the process from storage to shipment to maximize efficiency.

How important is inventory management in warehousing and distribution?

It’s critical. Good inventory management keeps track of stock levels, manages reordering, and predicts demand to ensure the right products are available and ready to ship, minimizing delays and reducing costs.

What are some strategies for integrating warehousing and distribution?

Integration strategies include using technology like inventory management software to provide real-time data, optimizing warehouse layout for faster order fulfillment, and selecting strategic locations to minimize transport time and costs.

Call us at 817-870-1311