How Do You Improve Order Processing?

Built For

Brad Bearden, Product Manager of Acctivate inventory software, discusses the difference an order processing system makes to become more efficient, productive, communicative, and balanced with your supply and demand.

How Do You Improve Order Processing?

Let’s say it’s a regular Tuesday afternoon, and your latest promo just hit the sweet spot—orders are pouring in like coffee at an early morning meeting. But there’s a hitch: if your order processing is as sluggish as a Monday morning without that coffee, you’re in for some trouble. That’s where order processing comes in—it’s the heartbeat of your operations, ensuring that what your customers buy becomes what they’re thrilled to receive.

One of the most frequently asked questions we hear is: How Do You Improve Order Processing?

Businesses know it’s the behind-the-scenes secret that can turn a one-time buyer into a lifetime fan. But it’s not just about shuffling papers and packing boxes; it’s about creating a seamless symphony that turns chaos into cash flow.

A polished order processing system can mean the difference between a wallet full of profits and a cart full of abandoned dreams. It’s about dazzling your customers with lightning-fast service, shrinking the room for errors until they’re just a tiny speck, and keeping your inventory as balanced as a yogi on a good day.

Understanding Your Current Process

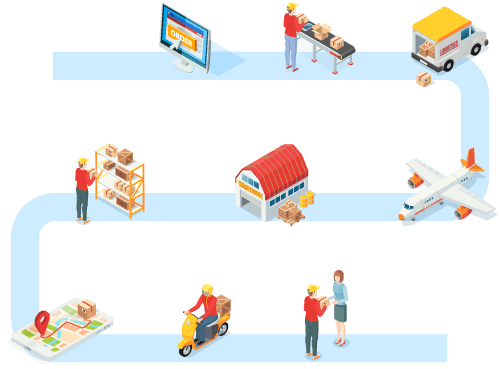

Before you can master the art of order processing, you have to know the dance steps you’re currently taking—step by toe-tapping step. It’s about getting down to the nitty-gritty of what happens after customers place an order. So, let’s roll up our sleeves and play detective in our businesses.

Start With What You Know

You probably have some process in place, even if it’s as basic as “get the order, send the order.” That’s a start, but let’s break it down. Map out each stage your order goes through, from the moment it’s received to the final goodbye as it heads off to the customer. Use tools as simple as a whiteboard or as fancy as flowchart software—whatever helps you visualize the workflow.

Identify the Bottlenecks

As you lay out your process, watch for those pesky bottlenecks. It could be that ancient printer that jams more than it prints or the step where everyone needs to double-check an address. Whatever they are, highlight them. They’re your first targets for improvement.

Ask the Warehouse Team

There’s no one better to spot the hitches in your system than the people who live and breathe it daily. Gather insights from your team—what frustrates them? What do they think takes longer than it should? This goldmine of frontline intel is invaluable.

Pitfalls and Potential

Some common pitfalls might include manual data entry (hello, human error), lack of inventory visibility (leading to the dreaded out-of-stock email), or communication mishaps (like when the sales team says “yes” and the warehouse team says “huh?”). Recognizing these allows you to pinpoint potential areas for immediate impact.

Baseline and Benchmark

Once you’ve mapped out your process and identified the pain points, set some baseline metrics. How long does each step take? How many orders go through a hiccup? These numbers are your benchmarks—your “before” photo, if you will—so you can measure your progress as you implement changes.

Understanding your current order processing system isn’t just busy work; it’s the first chapter in your epic saga of business optimization. Knowing where you are now sets the stage for every improvement to come, each one bringing you closer to that standing ovation from customers and team members alike.

Leveraging Technology for Efficiency

Now that we have the lay of the land, it’s time to bring in inventory and order management software. Let’s dive into how this technology can turn your order processing into a sleek, smooth-running machine.

Choosing Your Tech Partner Wisely

First things first, you’ve got to pick the right software. It’s like dating—except you’re trying to find the perfect match for your business needs. Look for software that integrates easily with your accounting software, which for most small and mid-sized businesses means QuickBooks. The goal is a seamless flow of information from one platform to another.

Automating the Mundane

Imagine never having to enter an order again manually. That’s not a pipe dream; it’s what order management software does best. It takes orders from all your channels—online, in-person, EDI, carrier pigeon (just kidding)—and puts them all in one place. Suddenly, you have more time to spend on things that require a human touch, like customer service or negotiating with suppliers.

Real-time Inventory Tracking

Remember playing hide and seek with your inventory? “Found you! No, wait, that’s an empty box…” With real-time inventory tracking, you’ll know exactly what’s in stock, what’s flying off the shelves, and what’s collecting dust. This means fewer backorders, fewer disappointed customers, and fewer surprise inventory buying sprees.

Data-Driven Decisions

One of the most incredible things about inventory and order management software is the data it gives you. Want to know which products are your best sellers by the hour, or what color t-shirt is the favorite in the summer versus the spring? This data can guide your purchasing, marketing, and sales strategies, making sure you’re as efficient as they come.

Set It and Forget It (Almost)

With the proper setup, your new inventory and order management software can handle much of the heavy lifting for you. Automated stock level alerts, re-order reminders, and even automated purchase orders are all part of the package.

Establishing Clear Communication Channels

Clear communication—internally with your team and externally with your customers—is critical for smooth order processing. When messages zigzag without hiccups, orders flow like a dream. Here’s how you can turn your business into a communication haven.

For Customers: Clarity is King

- Set Expectations: From the get-go, let your customers know what to expect—clearly state processing times, shipping days, and return policies.

- Order Confirmations: Once an order is placed, send a confirmation faster than you can say, “Thank you for your purchase!” The digital nod tells your customers, “We have your order, and it’s in good hands.”

- Keep Them Posted: Send updates like you’re keeping a friend in the loop. Order packed? Let them know. Shipped? Give them a virtual wave as their package starts its journey. A tracking number? That’s the golden ticket they’re waiting for.

For Your Team: Synchronize to Synergize

- Centralize Communication: A centralized order management system keeps everyone in the company on the same page regardless of where the order originated, which warehouse shipped the product, and who has spoken with the customer.

- Speak the Same Language: Create a standardized set of terms and protocols everyone understands. If “ASAP” to one person is “whenever” to another, you have a recipe for confusion.

- Feedback Loops Are Your Friend: Encourage and establish regular check-ins where team members can voice concerns and share updates.

Remember, when everyone’s in the loop, the likelihood of mistakes drops, and productivity skyrockets. It’s all about crafting a narrative of transparency and efficiency that runs through every facet of your order-processing story.

Monitoring and Improving Inventory Management

When spinning the plates of a bustling business, keeping an eye on your inventory means balancing what you have, what you need, and what you’re about to need. Let’s look at how to keep your inventory in superhero shape.

Keeping a Watchful Eye

- Track in Real-Time: Just like updating your status online lets your friends know what you’re up to, real-time inventory tracking keeps you in the know. It’s about having the 411 on every item, in every size, at any moment.

- Tech Tools to the Rescue: Barcode scanners and inventory management software make tracking a breeze, reducing errors and saving you from the old “oops, we sold something we don’t have” snafu.

Just-Right Inventory

- Predictive Purchasing: Use historical sales data and trends to anticipate what you’ll need.

- Avoid the Overstock Trap: Stocking up like there’s no tomorrow can backfire. Unsold goods are like money sitting on a shelf, gathering dust. Keep stock lean, mean, and ready to move.

- Safety Stock: Sure, having a cushion is comfy, but you don’t need a mountain of safety stock. Calculate the minimum you need to prevent stockouts without overdoing it.

Data-Driven Decisions

- Analyze: Crunch the numbers regularly. Which items are the movers and shakers, and which are the wallflowers? Adjust your inventory accordingly, and you’ll dance to better cash flow.

- Listen to the Numbers: Sales patterns, seasonal shifts, even global events—let the data tell you their stories. This way, you’re ordering smarter, not harder.

Tightening the Feedback Loop

- Listen to the Frontline: Your sales and warehouse teams are the boots on the ground. They often have first-hand insights into what’s flying off the shelves or what’s consistently being returned.

- Customer Feedback Matters: Reviews and customer questions can tell you what’s working and what’s not. Pay attention to and adjust your inventory according to what your customers tell you.

Inventory management isn’t just about counting boxes; it’s a strategic piece of the puzzle that can sharpen your competitive edge. Get it right, and you’ll have just what you need, just when you need it—ensuring every order is a promise kept.

FAQs about Improving Order Processing

What’s the best way to reduce order processing errors?

Start by automating as much of the process as possible to minimize errors. Implement an inventory and order management system to help with accurate data entry and inventory tracking.

How can I make my order processing faster?

Speed up your order processing by integrating all of your sales channels with your order management system for real-time data syncing. Optimize your warehouse layout for efficient picking and packing, and consider batch processing orders to streamline operations.

What are some signs that my order processing system needs improvement?

Keep an eye out for frequent stockouts or overstock, high numbers of customer complaints regarding order accuracy or delivery times, and if your staff is overwhelmed with manual tasks that could be automated. These are clear indicators that your system could use an upgrade.

Can improving order processing impact customer satisfaction?

Absolutely! Efficient order processing leads to faster delivery times, accurate orders, and better communication, all of which contribute to a positive customer experience.

Call us at 817-870-1311