What is dead inventory?

Built For

Have you ever walked into the warehouse or even peered into the depths of your own closet and stumbled upon items that haven’t seen the light of day in what feels like eons? Those products collecting dust on the shelves, forgotten and unsold, are called Dead Inventory. It’s the kind of stock that silently screams, “Remember me?” every time you pass by.

But, “what is dead inventory?” and why is it a bigger deal than just a forgotten box of last season’s trends? In this article, we’ll dig into the concept of dead inventory — the villain of businesses that can drag down profits and clutter valuable space. We’ll explore what causes inventory to become “dead,” how it impacts businesses, and most importantly, what can prevent it from happening in the first place. So, buckle up and get ready to breathe new life into one of the forgotten corners of inventory management.

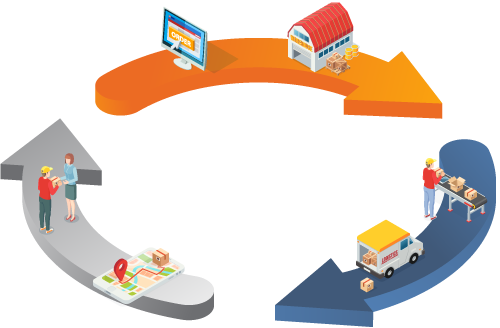

The Life Cycle of Inventory: From Fresh to Forgotten

Inventory is a bit like produce in a grocery store. When it first arrives, it’s fresh and full of potential. Over time, if not sold, it starts to wilt, taking up space without contributing to the store’s health or profits. Here’s how inventory can go from this season’s must-have to a warehouse wallflower:

- Arrival of goods: New products are introduced with excitement and anticipation. They’re the stars of the show, positioned to sell and sell quickly.

- Peak season: This is when inventory moves! With demand, products fly off the shelves, and everything seems great.

- The slowdown: Trends change, demand shifts, and certain items lose their luster. They sell less frequently, and restocking priorities shift.

- Stagnation: These items are now in limbo. They aren’t selling, but they’re not yet classified as “dead.” They’re the slow movers, often overlooked for the newer, shinier products.

- Decline into dead inventory: Finally, products not sold for an extended period become dead inventory. They’re no longer contributing to sales and costing you more than shelf space.

Why Inventory Turns into a Graveyard

Even the best products can end up in the graveyard of dead inventory. It’s not always about the quality of the goods; sometimes, it’s the circumstances. Here’s what typically leads inventory to become dead:

- Overestimating demand: The classic case of eyes bigger than your stomach. Businesses sometimes over-purchase based on optimistic sales forecasts that don’t pan out.

- Market trends and consumer shifts: What’s hot today can be ice-cold tomorrow. The market is fickle, and changes in consumer preferences can render a hot-selling item obsolete in no time.

- Inadequate marketing efforts: If a tree falls in the woods with no one around, does it make a sound? Similarly, if a product is on the shelf but no one knows about it, does it exist for consumers?

- Pricing problems: Setting the price too high can deter buyers, but slashing prices too frequently may lead customers to devalue the product.

- Seasonality: Timing is everything. Seasonal items have a shelf life; if they don’t sell within their window, they’re likely to join the ranks of the dead.

- Supplier issues: Sometimes, the problem starts at the source. Supplier delays or discontinuations can disrupt the sales cycle, leading to excess inventory that eventually goes unsold.

- Inventory management mishaps: A lack of effective inventory management strategies can lead to overstocking, understocking, and, ultimately, dead inventory.

Recognizing the Zombies Among Us: Identifying Dead Inventory

Like in a zombie movie, sometimes what’s dead doesn’t always look dead. It can lurk among your bestsellers and seasonal favorites, masquerading as viable stock. Here’s how to spot the living dead:

- Time check: Look at the age of your inventory. Products that have been sitting for months or even years without a sale are prime suspects.

- Demand pulse: Analyze sales data. A steady decline to zero can signal that a product’s life cycle is over.

- Market trends: Stay aware of what’s in and what’s out. If the market has moved on but your inventory hasn’t, it’s time to take action.

- Physical space: Dead inventory often consumes prime real estate in your storage area. If you notice overstocked items that never move, you might have a problem.

- Financial impact: Regularly check how much of your capital is tied up in unsold goods. A high percentage could indicate a graveyard of dead stock.

How Inventory Management Software Can Prevent Dead Stock

In the battle against dead inventory, technology is your best ally. You can stay ahead of the dead stock curve with inventory management software. Here’s how inventory software solutions can help keep inventory alive and kicking:

Real-Time Tracking

Inventory software provides real-time visibility and insights into stock levels, helping you make informed decisions on what to reorder and when.

Sales Forecasting

Analyze past sales data to predict future trends, allowing you to adjust purchasing accordingly.

Reorder Alerts

Set minimum stock levels in your inventory system, and when inventory dips below, the inventory management software sends reorder alerts for the products, preventing both overstock and stockouts.

Supplier Performance Analysis

Track which suppliers frequently lead to dead stock. Purchasing management data helps you negotiate better terms or decide when to switch to more reliable partners.

Aging Reports

Generate reports showing how long items have been in inventory, flagging products at risk of becoming dead stock.

Seasonal Trend Tracking

Keep ahead of seasonal curves by analyzing which items sell during different times of the year, helping you to plan special promotions or sales.

The Final Nail in the Coffin for Dead Inventory

In the quest to conquer the ever-looming shadow of dead inventory, we’ve uncovered that it’s not just about clearing out old stock but preventing it from accumulating in the first place. By identifying the early warning signs and taking swift action, businesses can keep their inventory fresh and dynamic.

We’ve explored the life cycle of inventory, from the exciting arrival of new stock to the dreaded stagnation period that signals a decline. We’ve armed you with the tools to identify and resuscitate dead stock through various creative strategies, from slashing prices to embracing the power of donations or recycling.

Most importantly, we’ve seen how inventory management software offers real-time tracking, sales forecasting, automated reordering, and a wealth of data to keep dead inventory at bay. By harnessing technology, companies make informed decisions, optimize their inventory, and maintain a healthier bottom line.

So, let’s put the final nail in the coffin for dead inventory. With the insights and strategies from this article, you’re now equipped to turn what was once a retailer’s nightmare into a manageable and even avoidable aspect of running a successful business.

Frequently Asked Questions (FAQs) About Dead Inventory

What is dead inventory?

Dead inventory refers to stock that has not sold for an extended period of time and is unlikely to sell in the future. It ties up capital and storage space without contributing to revenue.

Does dead inventory affect my business?

Dead inventory can significantly impact your business by reducing cash flow, taking up storage space, increasing handling costs, and potentially leading to additional markdowns, which can devalue your brand’s perception.

How can inventory management software prevent dead inventory?

Inventory management software can help prevent dead inventory by providing real-time data, sales forecasting, threshold-based reorder alerts, supplier performance tracking, and seasonal trend analysis to maintain optimal stock levels.

Is it possible to completely eliminate dead inventory?

While it’s challenging to eliminate dead inventory completely, proactive management and the use of technology can significantly reduce its occurrence. Regular review and adjustment of inventory practices are crucial to minimizing dead stock.

How does inventory software deal with the issue of phantom inventory?

Inventory software tracks actual sales and stock levels in real time, reducing the likelihood of phantom inventory – items that appear in stock in the system but aren’t physically available, helping ensure that purchase orders are accurate and preventing out-of-stock situations.

Will implementing inventory forecasting software affect other areas of my business?

Yes, in a positive way. Sales analysis provided by the software can lead to better purchasing and production planning, improved ROI on marketing plans, more efficient supply chain management, and enhanced overall service for your most profitable customers, benefiting the entire business operation.

Call us at 817-870-1311