What is inventory turnover rate?

Built For

Why “What is inventory turnover rate?” is such an essential question for product-centric businesses

Think of inventory turnover as the heartbeat of a company’s warehouse. The inventory turnover rate tells you how fast products fly off the shelves. Imagine a fresh batch of sneakers coming in, and before you know it, they’re out the door to happy feet everywhere – that’s your inventory doing a great job at keeping up with the pace!

Now, why is the inventory turnover rate such a big deal? It’s like having just the right amount of food in your fridge. Too much, and you might have to toss some when it goes bad; too little, and you’re running to the store in your pajamas. In business, having too much inventory means your cash is stuck in the form of slow-moving sneakers, gadgets, or whatever you’re selling, and that’s not helping anyone. But if you’ve got too little, customers are disappointed and probably turn to other sources when what they want or need is not available.

Managing inventory levels is a delicate balance. If a company has too much inventory, it ties up capital that could be used elsewhere, increasing storage costs, insurance, and potential spoilage costs. Conversely, too little stock can lead to stockouts, missed sales opportunities, and potentially dissatisfied customers.

Inventory turnover is a critical metric because it helps businesses:

- Optimize inventory levels. By tracking how quickly inventory is sold, companies can adjust their purchasing patterns to maintain a level of stock that meets customer demand without being excessive.

- Improve cash flow. Faster turnover means that money is not tied up.

So, “What is Inventory Turnover Rate?” and how is it calculated?

The inventory turnover rate is a step-by-step measure of how often your items get off the shelves and into your customers’ hands. In simple terms, it’s all about how many times your company’s products are sold and replaced in a certain period, usually year over year.

Here’s how the inventory rate is calculated:

Inventory Turnover Rate = Cost of Goods Sold / Average Inventory

- Cost of Goods Sold (COGS) is how much you’ve spent on the goods you’ve sold.

- Average inventory is the average value of the stock you’ve had in stock over the same time.

For example, let’s say your business sold $100,000 worth of widgets this year (COGS), and, on average, you had $25,000 worth of these widgets waiting to be sold to customers (average inventory).

Now, we do the math. Your inventory turnover rate would be $100,000 divided by $25,000, giving us 4.0.

What does that number mean? It’s telling you that you’ve sold and restocked your entire inventory four times over the year – your inventory turnover rate.

By understanding and keeping tabs on this number, you can better understand the rhythm of your business needs, ensuring you have the right amount of stock to keep your customers happy and your storage costs down. It’s all about staying in sync.

Inventory turnover rate: Keeping everything flowing just right

Ever wonder what keeps a business ticking along smoothly? One word: flow. And when it comes to keeping everything flowing just right, the inventory turnover rate steps up as the unsung hero. The inventory turnover rate dramatically affects a company’s financial and operational performance.

Cash flow champion

When inventory turns over quickly, it’s like a relay race where the baton is passed swiftly from one runner to the next. Each handover represents a sale; the faster this happens, the quicker your business gets cash in hand. This speedy cycle means less money tied up in products sitting around and more cash pumping through the business’s veins, ready for action.

Profitability pro

Selling stuff is great, but selling it quickly is even better. A high inventory turnover rate often means you’re not just selling; you’re selling efficiently. This efficiency can lead to lower storage costs, less wasted stock, and a better bottom line.

Operational efficiency expert

Efficiency is the name of the game, and inventory turnover rate is the scoreboard. A good score shows that you’re managing your stock like a pro. It tells you that your business is well-tuned and that you’re using resources wisely on products that gather dust.

KPI sidekick

Let’s discuss how inventory turnover stacks up against other key performance indicators (KPIs). Think of KPIs like a dashboard of dials and gauges in a car. While the inventory turnover rate is like the speedometer showing how fast you’re going, other KPIs might measure how much fuel you’re using or how efficiently you’re driving. Together, they give you a complete picture of performance. Inventory turnover rate holds its own among these metrics by showing how well capital is being used to generate sales. It’s not the only indicator you need, but without it, you’re driving with a blindfold on.

Inventory turnover rate industry benchmarks

Just like the perfect outfit varies depending on the occasion, determining a “good” inventory turnover rate depends on the industry. It’s all about context – the rate isn’t a one-size-fits-all figure.

If you’re in the fast-paced world of fresh foods, your inventory turnover rate better be quick – think of those avocados that go from rock-hard to too-ripe in a blink. But if you’re a packaged foods importer or in the fine wine business, you have a bit more time to work with. You have to find the rhythm that matches your industry.

Here’s how you can look at it:

- Fashion: Apparel retailers might see turnover as high as eight or more times a year. Quick change, quick sales!

- Tech gadgets: Technology products might have moderate turnover rates, given the blend of hot new releases and staple products.

- Heavy machinery: These big-ticket items don’t fly off the shelves daily, resulting in lower turnover rates.

Knowing your industry standard for inventory turnover is like navigating your business ship properly. If your turnover is slower than the industry average, you might be steering towards a storage-cost iceberg. Faster than average? You could be riding the winds of high demand. This metric helps you adjust the sails and set the course for profitable shores.

Inventory turnover rate influences

Inventory turnover rate isn’t just about counting boxes or tallying receipts; several factors influence it, and understanding them can help you fine-tune your business’ inventory rhythm.

Buying smarts

The dance begins with how and when you buy your stock. If you’re snapping up products faster than a trending meme, you could end up with a warehouse with piles and piles of surplus stock. Conversely, moving too slowly could mean missing out on the next big thing. Smart purchasing is about matching your moves to market demand.

Forecasting finesse

Sales forecasting is about predicting the hits before they top the charts. Get it right, and you stock what sells when it sells. Get it wrong, and you’re that DJ playing Christmas jingles in July. A sharp forecast keeps your turnover in tune with the times.

Demand dynamics

Demand can surge like a summer blockbuster or fade like last season’s colors. Your inventory turnover rate is riding this wave, so pay attention to the buzz. Are your products the talk of the town or yesterday’s news? Keeping a finger on the pulse of a product’s popularity helps you keep your inventory moving.

Price points

Pricing is more art than science. Price too high, and your products might gather dust; price too low, and they’re out the door without much to show for it. Finding that pricing sweet spot is about making your products irresistible without giving them away.

Seasonal swings

Every business has its seasons – literal or figurative. Bathing suits don’t sell in a snowstorm, and snow shovels don’t go in a heatwave. Your inventory turnover rate will naturally wax and wane with these seasonal swings. The trick is to not let them catch you off guard.

By getting a grip on these factors, you’ll keep your inventory turnover rate healthy and make your business more responsive, adaptable, and ready for whatever the market runway throws your way.

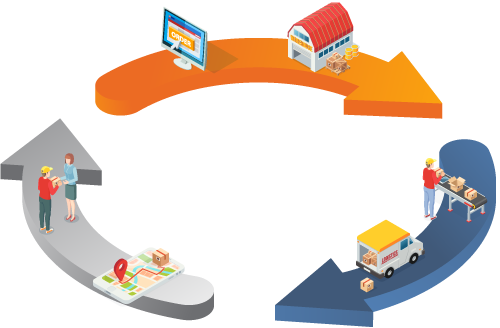

Optimizing inventory turnover rate with inventory management software

In the digital age, inventory management software is critical in optimizing inventory turnover rate and provides additional can’t-live-without features, including real-time inventory tracking, data analysis, order management, demand forecasting, and integration with QuickBooks.

Be always in the know with real-time tracking

Imagine having a bird’s-eye view of your stock levels 24/7. Inventory management software tracks every item as it comes in and goes out of your warehouse or warehouses, giving you a live feed of your inventory levels. No more guessing games or frantic stock takes.

Data-driven insights for better decisions

Inventory management software crunches numbers, spots trends, and provides insights via reports and dashboards. You’ll know which products are your stars and which are your benchwarmers, helping you make informed purchasing and sales decisions.

Accuracy and efficiency improvements

Even the best of us make mistakes. Inventory management software reduces human error and frees up your team to focus on what humans do best – being creative and managing instead of digging through spreadsheets.

Predictive power

With inventory management software, you’re not just looking at what’s hot right now; you’re peering into the future, predicting demand, and helping you stay one step ahead.

Integrated operations

Inventory management software isn’t a lone wolf; it plays well with others. Integration with QuickBooks provides access to advanced inventory, order, and purchasing tools while allowing your business to continue using QuickBooks for payroll and financial management.

By enlisting the help of inventory management software, you’re not just keeping up; you’re setting the pace. Inventory management software ensures your inventory turnover rate – and your business – stays supercharged.

Summary: FAQs about Inventory Turnover Rate

What is inventory turnover rate?

Inventory turnover rate is a measure that shows how many times a business has sold and replaced its inventory over a specific period, usually a year. It’s a vital sign of how well a company keeps its stock in line with customer demand.

Why is the inventory turnover rate important for businesses?

A healthy turnover rate indicates good product demand and efficient sales – meaning the business isn’t wasting money on excess inventory that sits unsold. It’s crucial for optimizing stock levels, improving cash flow, and maintaining operational efficiency.

How do you calculate inventory turnover rate?

You calculate the inventory turnover rate by dividing the cost of goods sold (COGS) by the average inventory. For example, if COGS is $100,000 and the average inventory is $25,000, the inventory turnover rate is 4. This means the company sold and replenished its inventory four times over the year.

What can influence my business’s inventory turnover rate?

Several factors affect turnover, including purchasing decisions, sales forecasting accuracy, demand for your products, pricing strategies, and seasonal trends. Each of these can make inventory move faster or slower through your system.

How does inventory management software improve inventory turnover?

Inventory management software offers real-time tracking, reduces errors through automation, provides valuable data-driven insights, helps with demand forecasting, and integrates with other systems like QuickBooks to streamline all aspects of inventory management.

What should my business’s inventory turnover rate be?

It varies widely by industry. For example, fashion retailers may turn their inventory eight or more times a year, while heavy machinery may have a much lower rate. The key is understanding your industry’s benchmark and striving for a rate that indicates strong demand without overstocking.

Call us at 817-870-1311