Slow Moving Inventory: How to Identify, Prevent, & Manage It

Built For

Slow-moving inventory quietly drains cash, consumes valuable warehouse space, and limits your ability to invest in products that actually sell. Left unaddressed, these underperforming items can quickly turn into excess or obsolete inventory, creating ongoing financial and operational strain.

In this guide, we break down what slow-moving inventory is, how to identify it using the right data, and proven ways to prevent and manage it. You’ll also see how inventory management tools like Acctivate help businesses gain visibility, make smarter decisions, and keep inventory working for—not against—their bottom line.

The Definition of Slow-Moving Inventory

Slow-moving inventory refers to products that sell at a much slower pace than expected based on the amount of stock on hand and the time it has been in inventory. These items may include raw materials, components, or finished goods that see little to no consistent demand over an extended period.

Because slow-moving items sit in storage longer, they tie up working capital and consume warehouse space while continuing to generate costs. If not identified early, slow-moving inventory can progress into excess inventory or become obsolete altogether, making it harder to recover value and increasing the financial impact on the business.

A Closer Look: What Is Slow-Moving Inventory?

Slow-moving inventory are inventoried items (both raw materials and finished goods) that have minimal customer demand based on the quantity on hand for a period of typically six months or greater.

The inactivity of these products contribute to wasted capital and resources by occupying warehouse space and incurring costs in the form of the following:

- Loans or credit lines to finance purchased inventory

- Per unit purchase price

- Manufacturing costs

- Freight costs

- Carrying costs (i.e., warehouse rent, labor and insurance)

- Opportunity cost (loss associated with not being able to bring in new, faster moving inventory)

Identifying slow-moving products empowers businesses to invest more wisely and intervene with necessary business process adjustments before the products phase out into excess inventory (products that have been on hand for more than 12 months) and obsolete inventory (products that have had no usage in the last 12 months), which tend to be more difficult to revive or move.

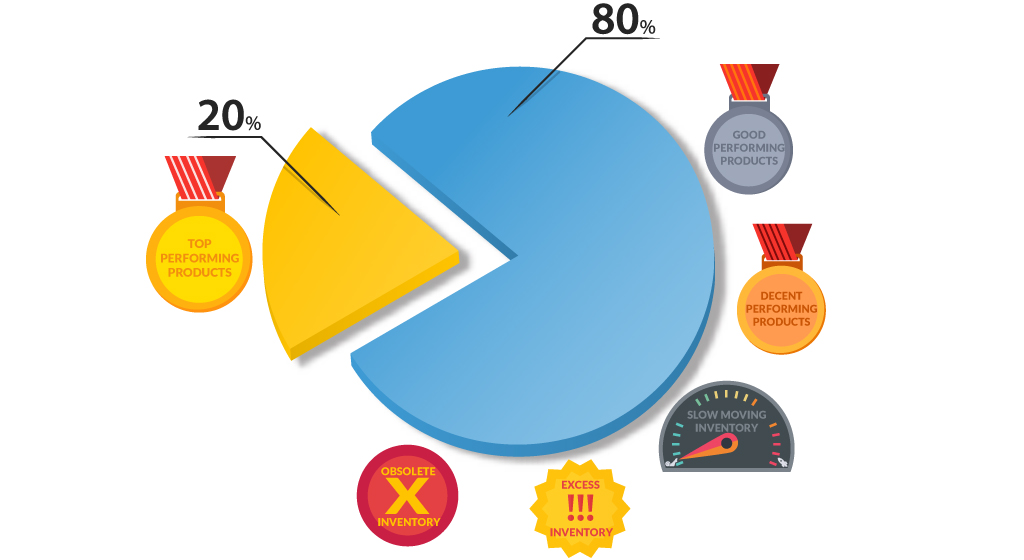

Consider product performance in relation to the general idea of the Pareto principle (also known as the 80/20 rule). The gist of the rule is that most things in life are unevenly distributed, therefore the majority (80%) of something is caused by a smaller percentage (20%) of something. A business example is 80% of sales are from 20% of products. The 20% are top performers contributing more value to the company meaning the other 80% could be good, decent or fall into categories of slow-moving, excess and obsolete.

Common Causes of Slow-Moving Inventory

Several factors can lead to inventory moving slower than expected. Understanding these causes can help businesses prevent items from becoming stagnant and tying up valuable resources.

- Overstocking or Poor Forecasting: Ordering too much of a product or relying on inaccurate sales forecasts can leave excess stock that doesn’t match actual demand.

- Seasonal or Trend-Driven Products: Items tied to specific seasons, trends, or promotions may sit unsold during off-peak periods, contributing to slow-moving inventory.

- Product Obsolescence: Technological advances, changes in customer preferences, or newer product versions can make older inventory outdated before it is sold.

- Ineffective Pricing or Marketing: Products that are priced too high, lack promotion, or are not positioned correctly in the market can remain unsold for longer periods.

- Supplier or Production Delays: Delays in receiving stock or producing items in bulk can disrupt inventory flow and result in mismatched stock levels.

- Limited Storage or Poor Warehouse Layout: Inefficient storage or hard-to-access locations can make certain products less visible or harder to pick, reducing turnover.

- Slow-Moving Product Categories: Some items naturally have lower demand due to niche markets, specialized use, or low frequency of purchase.

The Problem with Slow-Moving Inventory

Several factors can lead to inventory moving slower than expected. Understanding these causes can help businesses prevent items from becoming stagnant and tying up valuable resources.

- Tied-Up Capital: Inventory that doesn’t move ties up cash that could be used for high-demand products, investments, or other operational needs. This reduces liquidity and limits business flexibility.

- Increased Carrying Costs: Storing slow-moving items incurs costs such as warehouse rent, labor, insurance, and utilities. Over time, these expenses can outweigh the potential profit from the inventory.

- Risk of Obsolescence: Products that sit too long may become obsolete due to changing trends, technology, or customer preferences, leading to write-offs or forced discounting.

- Reduced Warehouse Efficiency: Slow-moving items occupy space that could otherwise be used for fast-selling products. This can create clutter, complicate picking processes, and reduce overall warehouse productivity.

- Lost Sales Opportunities: Capital and space consumed by slow-moving inventory limit the ability to stock high-demand products, potentially resulting in missed sales and dissatisfied customers.

- Inaccurate Forecasting: Excess slow-moving stock can distort demand forecasts, leading to over-ordering or under-ordering of other products and perpetuating inventory imbalances.

- Operational Strain: Managing stagnant inventory requires additional administrative attention for tracking, reporting, and clearance, diverting resources from more strategic business activities.

How to Identify Slow-Moving Inventory

Identifying slow-moving inventory is the first step to preventing financial strain and operational inefficiencies in your business. By systematically analyzing your stock, businesses can uncover underperforming items, free up warehouse space, and improve cash flow. Follow this step-by-step guide to identify slow-moving inventory effectively.

1. Analyze Inventory Turnover Rates

Start by calculating the inventory turnover rate for each product. Inventory turnover measures how often an item is sold and replaced within a specific period. Low turnover rates often indicate slow-moving stock. To calculate turnover, divide the cost of goods sold (COGS) by the average inventory value for the period. Products with significantly lower turnover than the average for your business may require closer examination.

2. Track Stock Aging

Determine how long each item has been sitting in your warehouse. This is often called “days in inventory” or “stock aging.” Items that remain unsold for extended periods—typically six months or longer—can be flagged as slow-moving. A well-maintained inventory management system can provide detailed aging reports to make this step quick and accurate.

3. Compare Historical & Forecasted Demand

Review historical sales data and compare it against your sales forecasts. Products that consistently underperform against predicted demand are likely slow-moving. This comparison highlights discrepancies in ordering or planning and helps pinpoint items that may be tying up capital unnecessarily.

4. Identify Seasonal or Trend-Dependent Products

Examine whether any inventory is tied to seasonal demand or specific trends. Items that only sell during certain times of the year may appear slow-moving in off-seasons but are still essential for peak periods. Properly categorizing these items ensures that seasonal fluctuations do not mislead inventory analysis.

5. Monitor Stock Levels Relative to Sales Volume

Compare the quantity of stock on hand to the average sales volume. If large quantities remain unsold over several months while other products move quickly, those items are likely slow-moving. This step also helps reveal overstocking issues that can amplify the negative impact of slow-moving products.

6. Evaluate Profit Margins & Carrying Costs

Slow-moving inventory doesn’t just tie up space—it also incurs carrying costs like storage, insurance, and depreciation. Evaluate the profit margins of low-turnover products against these costs. Items generating minimal profit while incurring significant holding expenses should be flagged for potential action.

7. Categorize & Prioritize Items

Once identified, categorize slow-moving items based on their urgency for action, such as aging, high carrying cost, or low turnover. Prioritize items that have the largest impact on working capital or warehouse space. This step allows businesses to focus on the products that matter most when implementing management or liquidation strategies.

8. Use Reporting & Visual Tools

Leverage reports, dashboards, and visual tools to make the identification process more efficient. Inventory reports that highlight low turnover items, aging stock, and underperforming SKUs provide a clear picture of inventory performance. Data visualization can help quickly spot trends and anomalies that might otherwise be missed.

9. Investigate Root Causes

Finally, look beyond the numbers to understand why certain products are moving slowly. Causes can include over-ordering, poor forecasting, ineffective pricing, limited marketing, or changing customer preferences. Identifying the root cause allows businesses to make informed decisions, whether it’s adjusting stock levels, repricing, bundling products, or discontinuing items.

Identifying Slow-Moving Inventory with Acctivate

Part of building efficient business strategies and succeeding is dependent upon knowing the details of how each product is performing. What is happening with the 80% or majority of products that are not high performers?

Businesses need to be able to uncover potential issues with the right metrics based on well-maintained product history and current performance to identify slow moving product as it continues to sit on warehouse shelves, tie up capital, lose value to customers, and veers into becoming obsolete.

Identifying the culprits requires knowing the age and demand of each product. What is the average time an item remained in stock before being shipped? How much of the product has been purchased during a given period as compared to its historical and forecasted demand? These metrics can reveal inventory turnover, which is how quickly products are moving from the warehouse to the customer and then being replenished. Low turnover is a red flag for slow moving inventory as it identifies product that is stagnant in the warehouse for a prolonged duration before being sold.

How much capital is being lost daily in storing low turnover items? All costs associated with supporting unsold inventory are carrying costs and when those costs are greater than the gross profit (the sale of the product minus direct costs to make the sale (Cost of Goods Sold)) a loss is being taken and there is low product demand present.

Access to accurate data for analysis is vital and more efficient when provided by an inventory management system, like Acctivate, that manages such data in one system for full visibility into inventory levels of every warehouse, along with inventory transaction and order history. Acctivate provides the real-time information businesses need in the form of a user-friendly Product List window for a quick snapshot data view, easy-to-read reports, and dashboard visuals that have built-in calculations to eliminate manual, error-prone figuring. Acctivate can easily reveal slow moving items to help businesses make intelligent decisions of what to do with the products and how to prevent the situation in the future.

How to Prevent Slow-Moving Inventory

Preventing slow-moving inventory is just as important as identifying it. Proactively managing stock ensures that capital isn’t tied up unnecessarily, warehouse space is optimized, and products continue to generate revenue. The following step-by-step guide outlines strategies businesses can implement to reduce the risk of slow-moving items before they accumulate.

1. Improve Demand Forecasting

Accurate demand forecasting is the foundation of preventing slow-moving inventory. Use historical sales data, seasonal trends, and market analysis to predict the quantity of each product that will sell in a given period. Incorporate factors such as promotions, upcoming product launches, and industry trends to make forecasts more precise. Better predictions allow for smarter purchasing decisions, reducing the likelihood of overstocking.

2. Implement Minimum & Maximum Stock Levels

Setting minimum and maximum stock levels helps maintain an optimal inventory balance. Minimum levels ensure you don’t run out of fast-moving products, while maximum levels prevent excess inventory from accumulating. Reviewing these levels regularly based on sales performance and changing customer demand ensures inventory remains lean and efficient.

3. Adopt a Just-In-Time (JIT) Approach

A Just-In-Time inventory strategy reduces the amount of stock held in the warehouse by aligning orders with actual demand. Ordering products closer to the time they are needed minimizes storage costs and decreases the risk of items becoming slow-moving. While JIT requires reliable suppliers and strong coordination, it’s highly effective in preventing inventory stagnation.

4. Regularly Review Product Performance

Conduct frequent inventory audits and performance reviews to identify potential slow-moving items early. Evaluate turnover rates, sales trends, and aging reports for all products. By catching early signs of stagnation, businesses can adjust purchasing or marketing strategies before inventory becomes an issue.

5. Optimize Product Mix & Assortment

Offer the right product mix based on customer demand and sales data. Avoid overloading your inventory with low-demand items, even if they seem attractive or trendy. Focus on stocking high-performing products while carefully managing niche or seasonal items. Periodically adjusting the product assortment prevents underperforming stock from taking up valuable space.

6. Improve Pricing & Promotion Strategies

Price and promotion strategies can significantly influence inventory movement. Items that are priced too high or not actively promoted may remain unsold. Implement competitive pricing, bundle complementary products, or run targeted promotions to encourage sales. Marketing strategies tailored to product performance help maintain steady inventory turnover.

7. Enhance Supplier & Production Flexibility

Work with suppliers and production teams to maintain flexibility in ordering and manufacturing. Shorter lead times and smaller order quantities allow you to adjust stock levels quickly based on real-time demand. Flexible supply chains reduce the risk of overstocking and make it easier to respond to shifts in customer preferences.

8. Monitor Customer Trends & Feedback

Pay close attention to customer behavior, feedback, and market trends. Changes in customer preferences can quickly render inventory slow-moving. Regularly surveying customers, tracking purchase patterns, and analyzing market data helps businesses stay ahead of trends and adjust inventory accordingly.

9. Leverage Inventory Management Tools

Using inventory management software helps prevent slow-moving stock by providing real-time visibility into inventory levels, sales patterns, and reorder points. Automated alerts, reporting, and analytics enable proactive decisions and minimize manual errors. By having a centralized view of your inventory, you can act before products stagnate.

10. Continuously Improve Processes

Preventing slow-moving inventory requires ongoing attention and process refinement. Evaluate the effectiveness of your inventory policies, forecasting, and supply chain strategies regularly. Adjust processes based on performance data, new insights, or changing business conditions. A culture of continuous improvement ensures your inventory stays lean and aligned with customer demand.

Preventing Slow-Moving Inventory with Acctivate

Slow-moving inventory can occur for different reasons, such as the introduction of new products, the start of the year, improper phasing out of previous product versions, or the end of seasons. But with the ability to identify such inventory, especially in a hassle-free manner via Acctivate, businesses can prevent the situation by better facilitating their purchasing and sales processes.

Consider the 80/20 rule in the instance of the customer base—the majority (80%) of a company’s customers are only interested in a lower percentage (20%) of their product offerings. With that said it is critical to have the operational and analytical data and tools to understand a customer’s needs and patterns and move forward with strategic decisions to meet customer expectations.

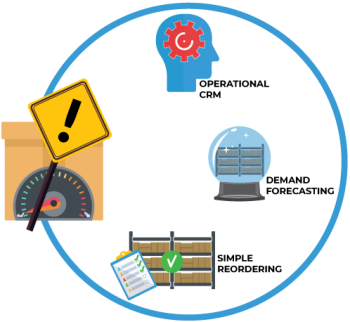

The operational CRM functionality of Acctivate captures every aspect of the buyer’s journey from quote-to-fulfillment to deliver complete visibility into each customer relationship per product. With this deeper insight, businesses can learn why there are changes that are slowing down inventory movement and make improvements, i.e., with communication between product development, sales, purchasing and inventory control departments and employ better forecasting and demand planning.

With the ability to better predict future buying and production needs based on sales usage and trends, the correct quantities can be purchased at the right times while improving inventory service levels. This reduces the risk of having slower moving products on the shelves cannibalizing capital, space, and faster moving product sales.

Acctivate provides forecasting reports to easily evaluate demand monthly or as needed. There are other reports, such as the minimum stock level analysis that details the quantity usage by product over different periods of time, and suggests a minimum stock level for inventoried items based on a user defined period of past usage. With the combined data of such reports, smart choices can be made for setting reorder points. Acctivate alerts users when it is time to reorder based on the established reorder points and makes replenishing inventory simple through an interface with minimal clicks to create multiple purchase orders at once per vendor.

How to Manage Slow-Moving Inventory

Even with preventive measures in place, some inventory will inevitably move slowly. Managing these items effectively is essential to protect working capital, optimize warehouse space, and maintain overall business efficiency. The following step-by-step guide outlines strategies for handling slow-moving inventory and turning potential losses into opportunities.

1. Identify & Categorize Slow-Moving Items

The first step in management is to pinpoint which products are slow-moving and categorize them by urgency, value, and potential for resale. Categorization can include items that are aging, high-cost, seasonal, or nearing obsolescence. Understanding the type and impact of each product helps prioritize the strategies you will apply, from promotional sales to special-order handling.

2. Evaluate Inventory Costs & Profitability

Assess the carrying costs, storage requirements, and profitability of slow-moving items. Products that incur high costs without delivering adequate return may need immediate attention, such as clearance or discount strategies. Conversely, items with moderate costs but strategic value may warrant retention and controlled management. This step ensures that management decisions align with your overall financial goals.

3. Implement Clearance or Discount Strategies

For items that are not performing, consider using discounts, promotions, or clearance sales to move them faster. Price reductions, bundled offers, or “buy-one-get-one” promotions can incentivize purchases and free up valuable warehouse space. Timely execution of these strategies prevents inventory from sitting too long and becoming obsolete.

4. Use Bundling or Kit Options

Bundling slow-moving products with popular items can help accelerate sales while maintaining profitability. Creating kits or packages allows businesses to sell excess inventory without significantly impacting margins. This strategy is especially useful for complementary products that enhance the overall value of the bundle.

5. Explore Alternative Sales Channels

Consider selling slow-moving inventory through alternative channels such as online marketplaces, secondary distributors, or outlet stores. Expanding the reach of these products increases the likelihood of sales while reducing the strain on your primary warehouse. Targeting new audiences can also uncover niche demand that may not have been captured through standard channels.

6. Implement Special Order or Dropshipping Processes

For products that must remain available for customer service or contractual reasons but do not move quickly, consider special order or dropshipping models. With special orders, items are purchased or produced only when a customer request arises, preventing stock from sitting idle. Dropshipping allows products to be shipped directly from suppliers to customers, freeing up storage space and reducing capital tied up in inventory.

7. Adjust Forecasting & Reordering Practices

Use insights from slow-moving items to refine future forecasting and reordering practices. Update minimum and maximum stock levels, review safety stock policies, and adjust purchasing strategies to prevent overstocking of low-demand products. Learning from historical performance ensures that future inventory aligns more closely with actual demand.

8. Consider Product Lifecycle Decisions

Evaluate whether certain slow-moving items should remain in your product lineup. Obsolete or outdated products may be better removed entirely, while seasonal or niche items might be kept for strategic reasons. Making timely lifecycle decisions prevents prolonged carrying costs and maintains a streamlined, profitable inventory.

9. Monitor Inventory Performance Continuously

Continuous monitoring of inventory metrics, such as turnover rates, stock aging, and sales performance, allows for early detection of new slow-moving products. Regular reporting and analysis help prevent minor issues from becoming larger problems, keeping inventory lean and manageable.

10. Integrate Cross-Department Collaboration

Managing slow-moving inventory is more effective when teams across purchasing, sales, marketing, and production collaborate. Sharing insights and coordinating strategies ensures that slow-moving products are addressed strategically, whether through pricing adjustments, promotional campaigns, or production changes. Collaboration reduces guesswork and aligns efforts to optimize inventory performance.

Managing Slow-Moving Inventory with Acctivate

When warehouse space and inventory is managed effectively, the majority (80%) of storage space should be used on the percentage (20%) of offerings that sell well. That stated, it is acknowledged that even with the means to identify and prevent slow-moving products, some items may still need to occupy warehouse space due to having to keep spare parts stocked to meet customer needs at any time to service equipment.

However, there are different steps that can be taken to maximize warehouse space for faster moving products and further manage slow-moving products. When deciding what approaches to take the industry and specific business model should be considered.

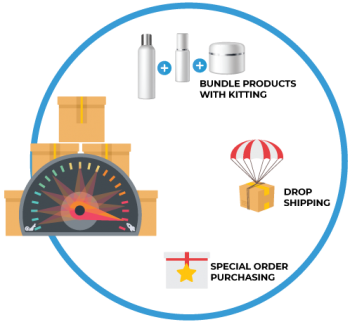

products that are proven to produce profit. Strategies can also be implemented to better sell product, such as with bundling. Slow-moving product can be bundled with faster moving products that complement each other or multiple quantities of the same product can be packaged together to sell more for less. In any of these cases, Acctivate is an efficient solution to manage the pricing and orders, as well as creating, selling, and managing kits for bundling product.

Better allocation can be implemented for slow-moving items that still must be sold to meet customer needs. The products can be sold, but not occupy physical warehouse space, by utilizing dropshipping and not affect demand forecasting of stocked items with special order purchasing.

With dropshipping, when a customer places an order, the seller places an order with the manufacturer or distributor who directly ships to the customer, eliminating the need for the product to tie up space and capital in the seller’s warehouse. Acctivate streamlines the dropshipping process by managing all dropship purchase orders in one spot that enables one-click sales order creation for each dropship vendor to complete the orders while maintaining solid customer relationships.

Slow-moving product may be considered product that is not a normal part of the purchase ordering process and in this case special ordering may meet the seller’s needs. With Acctivate, products can be designated as special order on sales orders or as special order products that will never be ordered for stock. The process is simple as Acctivate consolidates multiple scheduled sales orders with special order items for multiple customers into a single purchase order per vendor, which are received into and shipped out of the special-order warehouse as to not affect inventory stocking levels.

Slow-Moving Inventory FAQs

Can slow-moving inventory affect my business credit or financing?

Yes. Excess inventory ties up cash and can impact your working capital, which may influence your ability to secure loans or financing. Lenders often review inventory efficiency as part of financial health assessments.

How does slow-moving inventory impact customer satisfaction?

Slow-moving stock can limit warehouse space for high-demand products, potentially leading to stockouts or delays for popular items, which may frustrate customers and hurt repeat business.

Are there industries where slow-moving inventory is more common?

Certain industries, such as seasonal retail, electronics, and specialty manufacturing, are more prone to slow-moving inventory due to trends, technological changes, or niche demand.

Can slow-moving inventory ever be beneficial?

In some cases, slow-moving items may serve strategic purposes, like supporting long-term contracts, providing spare parts, or maintaining a complete product line. Careful management ensures they don’t drain resources unnecessarily.

How often should I review inventory to catch slow-moving items early?

Regular review is essential—monthly or quarterly evaluations can help identify slow-moving inventory before it becomes a financial burden, allowing for timely corrective actions like promotions, bundling, or special orders.

Identify, Prevent, & Manage Slow-Moving Inventory with Acctivate

Slow-moving product doesn’t have to be a continued hindrance within a business. With Acctivate inventory management software, such products can be identified, prevented, and managed along with all other products giving companies a complete business management system.

Learn more about Acctivate or contact CAI Software today!

Call us at 817-870-1311