Slow Moving Inventory: Identify, Prevent, Manage

Built For

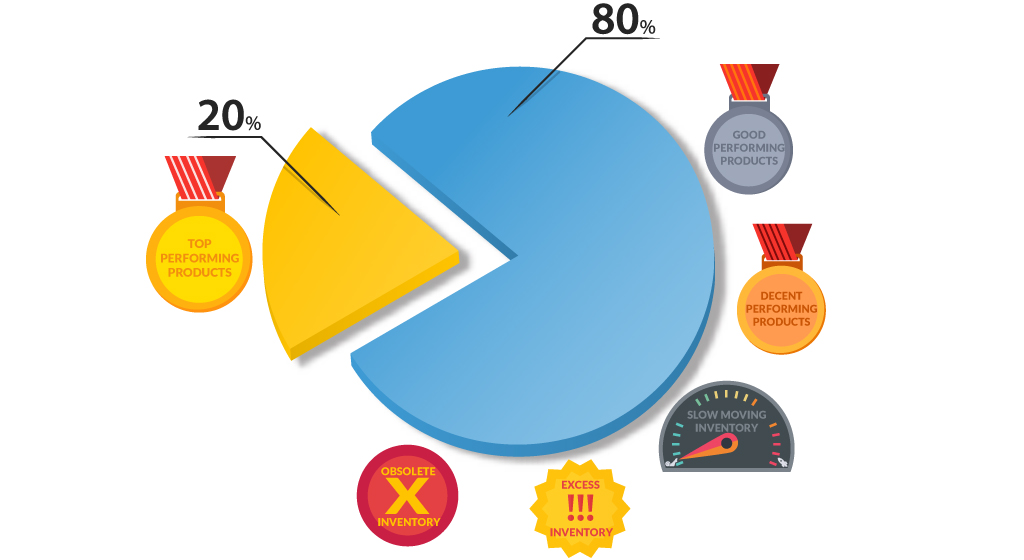

Consider product performance in relation to the general idea of the Pareto principle (also known as the 80/20 rule). The gist of the rule is that most things in life are unevenly distributed, therefore the majority (80%) of something is caused by a smaller percentage (20%) of something. A business example is 80% of sales are from 20% of products. The 20% are top performers contributing more value to the company meaning the other 80% could be good, decent or fall into categories of slow moving, excess and obsolete.

Slow moving inventory are inventoried items (both raw materials and finished goods) that have minimal customer demand based on the quantity on hand for a period of typically six months or greater.

The inactivity of these products contribute to wasted capital and resources by occupying warehouse space and incurring costs in the form of the following:

- Loans or credit lines to finance purchased inventory

- Per unit purchase price

- Manufacturing costs

- Freight costs

- Carrying costs (i.e., warehouse rent, labor and insurance)

- Opportunity cost (loss associated with not being able to bring in new, faster moving inventory)

Identifying slow moving products empowers businesses to invest more wisely and intervene with necessary business process adjustments before the products phase out into excess inventory (products that have been on hand for more than 12 months) and obsolete inventory (products that have had no usage in the last 12 months), which tend to be more difficult to revive or move.

Identify slow moving inventory

Part of building efficient business strategies and succeeding is dependent upon knowing the details of how each product is performing. What is happening with the 80% or majority of products that are not high performers?

Businesses need to be able to uncover potential issues with the right metrics based on well-maintained product history and current performance to identify slow moving product as it continues to sit on warehouse shelves, tie up capital, lose value to customers, and veers into becoming obsolete.

Identifying the culprits requires knowing the age and demand of each product. What is the average time an item remained in stock before being shipped? How much of the product has been purchased during a given period as compared to its historical and forecasted demand? These metrics can reveal inventory turnover, which is how quickly products are moving from the warehouse to the customer and then being replenished. Low turnover is a red flag for slow moving inventory as it identifies product that is stagnant in the warehouse for a prolonged duration before being sold.

How much capital is being lost daily in storing low turnover items? All costs associated with supporting unsold inventory are carrying costs and when those costs are greater than the gross profit (the sale of the product minus direct costs to make the sale (Cost of Goods Sold)) a loss is being taken and there is low product demand present.

Access to accurate data for analysis is vital and more efficient when provided by an inventory management system, like Acctivate, that manages such data in one system for full visibility into inventory levels of every warehouse, along with inventory transaction and order history. Acctivate provides the real-time information businesses need in the form of a user-friendly Product List window for a quick snapshot data view, easy-to-read reports, and dashboard visuals that have built-in calculations to eliminate manual, error-prone figuring. Acctivate can easily reveal slow moving items to help businesses make intelligent decisions of what to do with the products and how to prevent the situation in the future.

Prevent slow moving inventory

Slow moving inventory can occur for different reasons, such as the introduction of new products, the start of the year, improper phasing out of previous product versions, or the end of seasons. But with the ability to identify such inventory, especially in a hassle-free manner via Acctivate, businesses can prevent the situation by better facilitating their purchasing and sales processes.

Consider the 80/20 rule in the instance of the customer base—the majority (80%) of a company’s customers are only interested in a lower percentage (20%) of their product offerings. With that said it is critical to have the operational and analytical data and tools to understand a customer’s needs and patterns and move forward with strategic decisions to meet customer expectations.

The operational CRM functionality of Acctivate captures every aspect of the buyer’s journey from quote-to-fulfillment to deliver complete visibility into each customer relationship per product. With this deeper insight, businesses can learn why there are changes that are slowing down inventory movement and make improvements, i.e., with communication between product development, sales, purchasing and inventory control departments and employ better forecasting and demand planning.

With the ability to better predict future buying and production needs based on sales usage and trends, the correct quantities can be purchased at the right times while improving inventory service levels. This reduces the risk of having slower moving products on the shelves cannibalizing capital, space, and faster moving product sales.

Acctivate provides forecasting reports to easily evaluate demand monthly or as needed. There are other reports, such as the minimum stock level analysis that details the quantity usage by product over different periods of time, and suggests a minimum stock level for inventoried items based on a user defined period of past usage. With the combined data of such reports, smart choices can be made for setting reorder points. Acctivate alerts users when it is time to reorder based on the established reorder points and makes replenishing inventory simple through an interface with minimal clicks to create multiple purchase orders at once per vendor.

Manage slow moving inventory

When warehouse space and inventory is managed effectively, the majority (80%) of storage space should be used on the percentage (20%) of offerings that sell well. That stated, it is acknowledged that even with the means to identify and prevent slow moving products, some items may still need to occupy warehouse space due to having to keep spare parts stocked to meet customer needs at any time to service equipment.

However, there are different steps that can be taken to maximize warehouse space for faster moving products and further manage slow moving products. When deciding what approaches to take the industry and specific business model should be considered.

There are instances where slow moving products can be removed without the need to further manage them in stock. With products that move slowly due to being out of season, businesses will often run clearance sales. Consider selling the inventory at a low profit margin or a loss to be able to replace shelf space with fast moving products that are proven to produce profit. Strategies can also be implemented to better sell product, such as with bundling. Slow moving product can be bundled with faster moving products that complement each other or multiple quantities of the same product can be packaged together to sell more for less. In any of these cases, Acctivate is an efficient solution to manage the pricing and orders, as well as creating, selling, and managing kits for bundling product.

Better allocation can be implemented for slow moving items that still must be sold to meet customer needs. The products can be sold, but not occupy physical warehouse space, by utilizing dropshipping and not affect demand forecasting of stocked items with special order purchasing.

With dropshipping, when a customer places an order, the seller places an order with the manufacturer or distributor who directly ships to the customer, eliminating the need for the product to tie up space and capital in the seller’s warehouse. Acctivate streamlines the dropshipping process by managing all dropship purchase orders in one spot that enables one-click sales order creation for each dropship vendor to complete the orders while maintaining solid customer relationships.

Slow moving product may be considered product that is not a normal part of the purchase ordering process and in this case special ordering may meet the seller’s needs. With Acctivate, products can be designated as special order on sales orders or as special order products that will never be ordered for stock. The process is simple as Acctivate consolidates multiple scheduled sales orders with special order items for multiple customers into a single purchase order per vendor, which are received into and shipped out of the special-order warehouse as to not affect inventory stocking levels.

Slow moving product doesn’t have to be a continued hindrance within a business. With Acctivate Inventory Software, such products can be identified, prevented, and managed along with all other products giving companies a complete business management system.

Sources:

America Express OPEN Forum: Applying the 80/20 Rule to Your Inventory

McKinsey & Company: Turn slow-moving inventory into fast profits

Drive Your Success: At What Point Does Slow Moving Inventory Become Dead Inventory?

CFO Selections: How to Identify and Avoid Obsolete Inventory

Call us at 817-870-1311