Ensuring Accuracy of Orders

Built For

Ensuring Accuracy of Orders

Order accuracy is vital to a successful business. Imagine a customer eagerly waiting for their order, only to receive the wrong item or find out it’s out of stock. Frustrating, right?

Ensuring order accuracy is crucial not just for keeping customers happy but also for maintaining efficient business operations. With so many moving parts, from inventory tracking to order fulfillment, even a tiny mistake can lead to big problems. But don’t worry. Effective strategies and tools are available to help you achieve pinpoint accuracy with every order.

In this article, we’ll explore how inventory and order management software, barcode technology, and centralizing orders from all channels can make a world of difference. You’ll discover how to boost your order accuracy and keep your customers returning for more!

Using Inventory and Order Management Software

Inventory and order management software is necessary to ensure order accuracy, providing a comprehensive solution for tracking inventory in real time, automating order processing, and reducing human errors.

Real-Time Inventory Tracking

One of the most significant advantages of using inventory and order management software is real-time inventory tracking. With up-to-date information, you can easily monitor stock levels, manage reorders, and prevent stockouts or overstock situations. This accuracy ensures that when an order is placed, the items are actually available, eliminating the risk of backorders or delays.

Automated Order Processing

Manual order processing is prone to errors, from data entry mistakes to miscommunication between departments. Inventory and order management software automates these processes, ensuring that orders are accurately recorded, processed, and fulfilled. Automated systems can handle everything from generating picking lists to updating inventory records, significantly reducing the likelihood of errors.

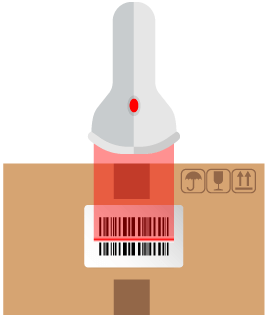

Implementing Barcode Technology

Barcode technology is an essential tool for ensuring order accuracy. It provides a reliable and efficient way to track and verify inventory, reducing human error and speeding up order processing. Here’s how implementing barcode technology can benefit your business:

Barcode Technology

Barcodes are unique codes assigned to products, which can be scanned using barcode scanners. Each barcode contains information about the product, such as its name, price, and stock-keeping unit (SKU). Barcode technology allows for quick and accurate data entry instead of manually inputting information, which can be time-consuming and error-prone.

Advantages of Using Barcodes for Tracking and Verifying Orders

Barcodes streamline the entire order fulfillment process. Here are some key benefits:

- Improved Accuracy: Scanning barcodes significantly reduces the risk of human error. Whether checking items as they are received or picking items in a warehouse, barcode scanning ensures the correct product is recorded.

- Speed and Efficiency: Barcode scanning is much faster than manual entry. This speed helps in processing orders quickly, which is especially beneficial during peak times or sales events.

- Real-Time Inventory Updates: The inventory and order management system is updated in real-time as items are scanned. This real-time tracking allows for accurate stock levels and helps in making informed decisions about reordering and stock management.

- Enhanced Traceability: Barcodes make tracking products’ movement through the supply chain easy. This traceability is crucial for quality control, recalling products if necessary, and maintaining detailed inventory records.

Implementing Barcode Technology in Your Business

To get started with barcode technology, you will need:

- Software: Inventory and order management software generates barcodes for your items and provides the functionality to convert scanned barcode data into useful, actionable information.

- Barcode Scanners: These devices read the barcodes and input the data into your system.

- Barcode Labels: Barcode labels are printed and attached to products and shelving.

Integrating barcode technology into your operations significantly enhances order accuracy, speeds up processes, and maintains better control over your inventory. It’s a cost-effective solution that substantially benefits businesses of all sizes.

Centralizing Orders from All Channels

Managing multiple sales channel orders can be daunting, but centralizing these orders can significantly enhance order accuracy and streamline your operations. By consolidating orders from various sources into a single system, you can ensure that nothing falls through the cracks and that each order is processed correctly and efficiently.

Challenges of Managing Orders from Multiple Sales Channels

With the rise of eCommerce, businesses often sell their products through various platforms, including online marketplaces, their own websites, EDI, and via a direct sales team. Each of these channels comes with its own set of challenges:

- Stock Discrepancies: Managing inventory across multiple channels can lead to discrepancies if stock levels are not updated in real time.

- Disparate Systems: Different platforms may use different systems, making it difficult to track orders cohesively.

- Manual Data Entry: Without integration, staff may need to manually enter order information from each channel into a central system, increasing the risk of errors.

How Centralizing Orders Helps in Ensuring Accuracy of Orders

Centralizing orders involves integrating all sales channels into a unified order management system. Here’s how this integration benefits your business:

- Improved Customer Experience: A centralized system helps provide consistent service levels across all sales channels, improving the overall customer experience.

- Streamlined Order Processing: With all orders flowing into a single system, you can streamline processing, ensuring that every order is handled efficiently and accurately.

- Real-Time Inventory Updates: A centralized system updates inventory levels in real time across all channels. This synchronization prevents overselling and stockouts, ensuring customers receive what they ordered.

- Reduced Errors: By automating the flow of order information from various channels into one system, you minimize manual data entry, reduce the risk of errors, and ensure that each order is processed correctly.

Integration with eCommerce & EDI Platforms

Inventory and order management software integrates with many eCommerce platforms, as well as online marketplaces, and EDI systems. This integration allows you to:

- Manage shipping and fulfillment from a centralized system, ensuring timely delivery and accurate order fulfillment.

- Import orders from these platforms into your central system.

- Sync inventory levels across all platforms so customers always see accurate stock information.

Best Practices for Ensuring Order Accuracy

Maintaining high order accuracy is crucial for businesses seeking to improve customer satisfaction and streamline operations. Here are some best practices to ensure your orders are consistently accurate:

Regularly Auditing and Updating Inventory Data

Regular audits of your inventory are essential for maintaining accuracy. Here’s how to keep your inventory data in check:

- Scheduled Audits: Conduct regular physical counts of your inventory to verify that the recorded stock levels match the actual counts. Depending on your business needs, this can be done monthly, quarterly, or annually.

- Cycle Counting: Instead of a full inventory count, cycle counting involves counting a portion of your inventory on a rotating basis. This method helps to identify and correct discrepancies more frequently.

- Data Reconciliation: Regularly compare your inventory records with actual stock levels and reconcile any differences. Use software to automate and streamline this process.

Training Staff on Accurate Order Picking and Packing Procedures

Proper training ensures your staff can pick and pack orders accurately, reducing errors. Key training areas include:

- Order Picking Techniques: Train employees on efficient and accurate picking methods, such as using pick lists or barcode scanners. Emphasize the importance of double-checking items before moving them to the packing area.

- Packing Procedures: Ensure staff know how to pack items securely to avoid damage during transit. Use checklists to verify that all ordered items are included and correctly filled.

- Quality Control: Implement a quality control step where a designated team member reviews orders before they are shipped. This extra layer of verification can catch errors before the order reaches the customer.

Implementing Quality Control Checks

Quality control checks are vital for catching errors before they affect your customers. Consider these strategies:

- Receiving Inspections: Check the quality and accuracy of incoming inventory before it is added to your stock. This helps to ensure that only the correct and undamaged items are stored.

- In-Process Checks: During order picking and packing, perform random checks to verify accuracy. This can be done by supervisors or through automated systems that flag discrepancies.

- Final Inspection: Conduct a final inspection before an order is shipped to ensure all items are packed correctly. This step can reduce the number of returns and customer complaints.

Leveraging Technology for Continuous Improvement

Technology can drastically enhance your ability to maintain order accuracy.

- Data Analytics: Use data analytics to identify order error trends and patterns. This information can help you pinpoint problem areas and implement targeted improvements.

- Automated Alerts: Set up automated alerts for issues such as low inventory levels or delays in order processing. These alerts enable you to address problems promptly.

- Scalable Solutions: Invest in scalable inventory and order management software that grows with your business. This ensures that your systems remain effective even as your order volume increases.

By regularly auditing inventory data, effectively training staff, implementing quality control checks, and leveraging technology, you can significantly improve your order accuracy. These best practices not only help prevent errors but also enhance overall efficiency, leading to happier customers and a more streamlined operation.

Call us at 817-870-1311