Built For

Intelligent Order Picking

Acctivate’s picklist feature boosts warehouse performance to meet daily order fulfillment demands with ease.

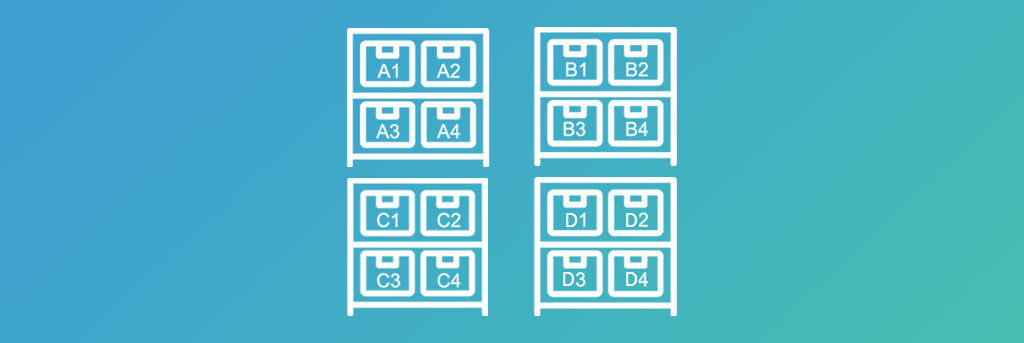

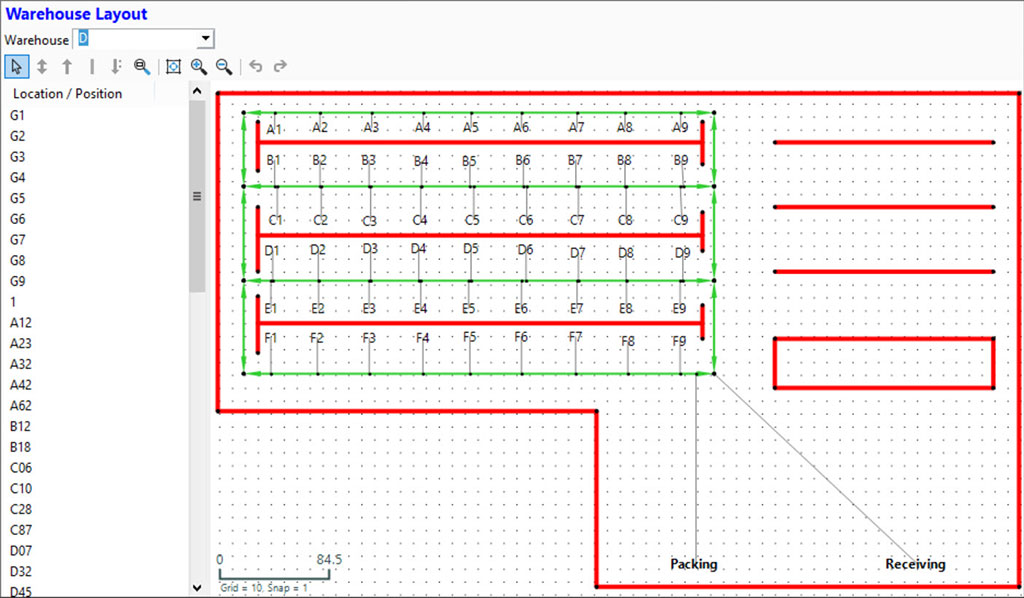

Define the layout of your entire warehouse including aisles, walls, end caps, bin locations and walking paths, allowing Acctivate to intelligently map the best routes for picking orders.

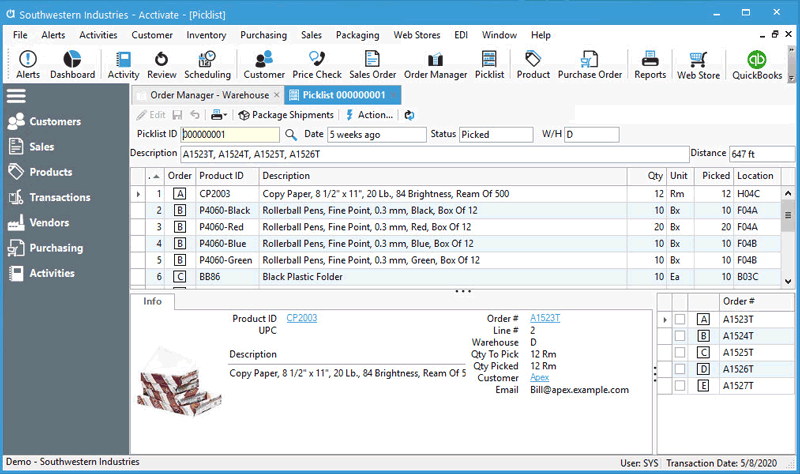

Pick multiple orders at once following a single picklist with a clear view of what to pick and where to go based on your defined warehouse layout.

Follow predetermined paths to warehouse bin-locations to maximize worker productivity and speed up fulfillment.

Track workflow stages of picking (i.e., ready to pick, in progress, picked, completed) with manual or automatic updates based upon sales order criteria or specific actions in the system.

Create picklists in multiple ways, including for a batch of orders in the Order Manager, directly from a single sales order or a configured “Next Action” button.

Follow picklists on a mobile device for even greater accuracy and speed with barcode scanning of picked products.

Call us at 817-870-1311

warehouse layout editor

Eliminate Inefficient Zigzagging & Increase Order Picking Productivity to Meet Daily Fulfillment Demands

Load your warehouse layout into Acctivate and define all aspects, including aisles, walls, end caps, walking paths, receiving, packing, and bin-locations. With the detailed layout, Acctivate will map the most logical and ideal routes throughout the warehouse and utilize that information on picklists to deliver the shortest paths to and from products across all orders.

With Acctivate’s intelligent mapping based on your warehouse layout, optimize picking and overall fulfillment.

intelligent picklist

Optimize & Accelerate Order Picking to Keep Workers and Customers Happy

Acctivate’s Picklist feature tracks picking efforts of all products on orders and the workflow stages of the picking process as the warehouse is navigated via optimal routes. Picklists are also available for mobile barcoding devices via Mobile Order Picking, adding even more precision to the process.

A single picklist consolidates multiple orders to enable batch picking and filling orders in a timely manner. The picklist includes the best picking routes automatically mapped by the Warehouse Layout Editor in Acctivate. Therefore, reducing time that each worker would otherwise spend thinking about the next product on the list or what bin location to go to next.

Explore more of Acctivate…

Call us at 817-870-1311